By: Grace Y. Tanchee

The importance of a mineral resource estimate for the long-term viability of a mine cannot be understated. Being a core basis of a mine’s feasibility study and evolving mine plans, a well-made and continuously updated resource model is essential to any mine looking to ensure profitability and sustainability. Strategizing based on an erroneous estimate can have disastrous results for a mine. As such, resource estimations must always be properly executed and well understood by the geologists, mine planners, and all other stakeholders.

THE CHALLENGE

Being crucial, resource geologists are expected to ensure that the resource estimates are accurate and compliant with standards. Geologists are also expected to update the model as new information becomes known. Time to complete and share is crucial here as updated models are used to refine the mine plan and avoid losses caused by outdated models.

There are challenges to contend with that can be the source of errors through-out each step of the estimation process, which in turn can reduce the accuracy of a resource estimate. For example, the source data could be insufficient or contain errors. Garbage in is garbage out. Improper tools and lack of information can also hamper the validation of data and thorough investigation, leading to a poor understanding of the deposit. This can affect the domaining model build, selection of the estimation method and parameters. Decentralized data and a lack of recording also heightens the risk of using incorrect data, and makes it difficult to trace and audit during the review process. Difficulties in coordinating can also increase the time crunch.

THE IMPROVEMENTS NEEDED

There are ways by we can minimize the risk of committing errors and help ensure that the resource estimate is as accurate as possible. One is by having proper and centralized data management. Just being able to store the data in one place is insufficient; data management should also include a means to record changes made to the data and why, and any important notes about the data. This will help provide context and auditability through-out the process, and help with future changes.

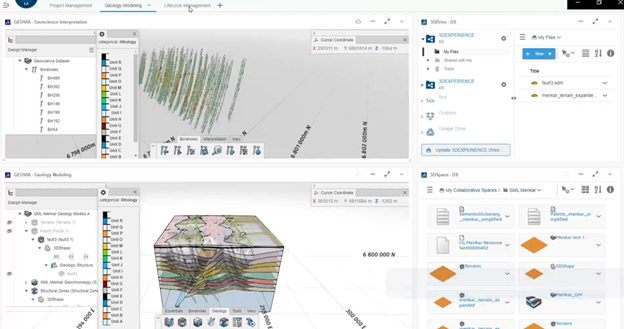

Next, the resource geologist must be able to visualize the data and have the tools for analysis and estimation. 3D Software with geology modelling tools can greatly help the geologist make sense of the data and render the model in a faster more efficient way.

Clear and traceable workflows can also be used to monitor and manage the process from start to finish, check that work is done based on best practices, and make sure that all stakeholders are fully informed and updated. Being structured, the flow of data and information between various stakeholders at each stage of the process can be made efficient.

All these can be enhanced via collaboration, facilitating knowledge sharing, feedback from fellow team members and consultants, and a collective understanding of the estimate.

THE SOLUTION

An effective way to conduct these improvements is through taking advantage of technological solutions to facilitate the changes needed. In line with this, Dassault Systemes (DS) has developed the Strategic Resource Modelling (SRM) solution. Through a combination of DS GEOVIA Surpac software and the 3DExperience platform, SRM is a comprehensive solution that links and manages processes, information, people, and tools under a single collaborative platform. Built to cover the many aspects affecting the resource estimation process, SRM is used to:

- Organize and manage geoscience data, ensure a single source of truth

- Build a unified view and understanding of the model

- Easily collaborate within and between teams

- View in 3D and share solid models via a browser, allowing for analysis anywhere anytime as long as connected

- Validate input data and generate consistent and robust resource models

- Enact based on project management principles and best practices

- Improve process efficiency, consistency, and time savings through workflows

- Utilize dashboarding and reporting capabilities to support strategic decision making

Resource estimation is the basis of multi-million investment decisions and subsequent mine plans that can make or break a mining company. If you want to know more how the DS Strategic Resource Modelling Solution can help ensure that reliable resource estimates are made, contact DS Philippine partner Paramina Earth Technologies Inc via paramina_solutions@paramina.com or reach us through www.paramina.com.