A case study at the GNPower coal power plant in Mariveles, Bataan (Photo credit: https://www.gnpower.com.ph/projects/)

GNPower Ltd. Co. (or “GNPower”) is a private limited partnership that was organised and established in 1997 by PMR Holding Corp. as its sole general partner and PMR Limited Co. as limited partner. The company aims to develop, operate and own power generation projects and associated facilities in the Philippines. Through the years, there were changes in the corporate structure and partnerships. By June 2014, the sole general partner of GNPower is GNPower Holdings GP Corporation which is owned by Power Partners, while Power Partners is the sole limited partner.

With regards to their coal energy project, it started way back in 2005. On that year, the partnership began the development of a coal-fired project. It was their first step in creating an “integrated, multi-fuel electricity generation and fuel handling energy complex”. [1]

Five years later, the GNPower began the construction of a 2x316MW (net) clean pulverized coal-fired power plant located in Mariveles, Bataan, Philippines (“Mariveles Project”). In this project, GNPower and Power Partners own a significant minority position through their ownership of GNPower Mariveles Coal Plant Ltd. Co. (GMCP). GMCP is the special purpose vehicle established to construct, own and operate the Mariveles Project. [1]

In 2013, the coal-fired facility was declared commercially available in the market. It is GNPower’s pioneer project and is the largest greenfield power project that was built in Luzon after the enactment of EPIRA in 2001.

GNPower Mariveles Coal Plant Ltd. Co. is now referred to as GNPower Mariveles Energy Center Ltd. Co.

Coal is considered a baseload energy resource in the Philippines as it is sufficiently cost-effective in providing a consistent supply of power. Currently, there are 28 coal-fired power plants operating throughout the Philippines. [2] One competitive and significant factor in the industry is the plant’s ability to supply adequate power while burning less coal in the process. In relation to this, a study was conducted by a group of experts to determine how cost-efficient is the operation in the Mariveles Coal Plant. What are the possible strategies they can or have implemented to assure boiler efficiency that utilizes less coal? What is the significance of this study with regards to protecting the environment through reduced carbon emission?

“A Study of the Changes in Efficiency of a Coal Fired Boiler Following the Conversion to a Dry Bottom Ash Handling System” is a study done by Artemio Boado (Plant Manager, Mariveles Power Plant), Zhao Peng (Engineering Manager, Qingdao Daneng), Steven Hou (General Manager, Int’l Business of Qingdao Daneng), Wang Yong (Chairman, Qingdao Daneng) and Edgardo B. Cruz (President, Philippine Coal Plant User Group).

The study aims to determine and analyse the boiler efficiency of Unit 2 of Phase 1 of GN Power Mariveles, according to measured data before and after the conversion of the bottom ash system from wet to dry which was implemented in March 2018. [3]

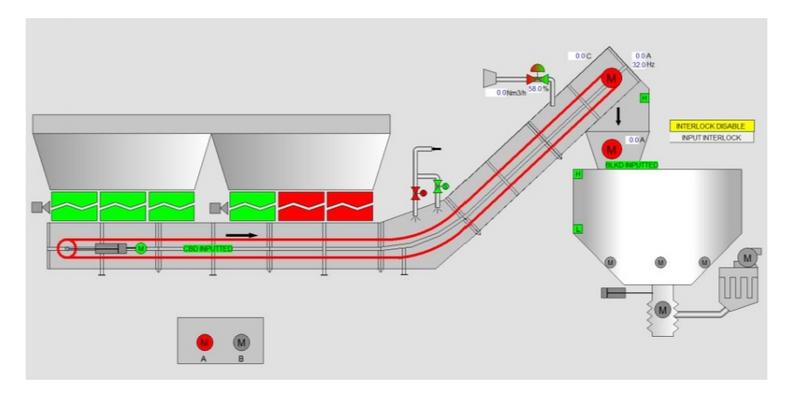

From their report, GN Power Mariveles Phase 1 consists of 2 x 340 MW T-fired sub critical coal fired boilers (Originally 2 x 316MW). The boilers were supplied by Harbin Boiler Company of China. This has a wet bottom handling system which consisted of a hopper under the boiler, sealing plate, submerged scraper conveyor, cooling water system, silo and discharger. The wet system was later converted to dry system by Qingdao Daneng Environmental Protection Equipment Incorporated Company (or Qingda) utilising their patented DUNOCON conveyor technology. “Both units were converted and commissioned in a standard scheduled 30-day boiler outage with Unit 2 converted in March 2018 and Unit 1 in February 2019. Since commissioning, both units dry bottom ash systems have operated well and without issue.” [3]

“When considering a pulverised coal fired boiler, the application of dry bottom ash handling technology is well proven and has several key advantages over those utilising water for the cooling and transportation of bottom ash. Along with the elimination of water handling and treatment, reduced power consumption, reduced maintenance etc, a significant amount of energy can be returned to the boiler from the reduction of energy losses at the boiler throat, waste heat from the bottom ash and the reduction of unburnt carbon in the bottom ash.” [3]

“However, in order to realise these potential benefits, the dry bottom ash system needs to be carefully designed and operated to ensure that the cooling air quantity and distribution through the conveyor and into the boiler are optimised.” [3]

Boiler efficiency testing standard

For this study, the efficiency of the boiler unit is determined basically by following the testing standard ASME PTC-4.1. (Further calculation methods not considered in ASME PTC-4.1 have been supplemented to compute for the credits specifically due to the adoption of dry bottom ash technology. [3])

There are two ways to compute for the boiler efficiency testing: (1) direct method (2) indirect method.

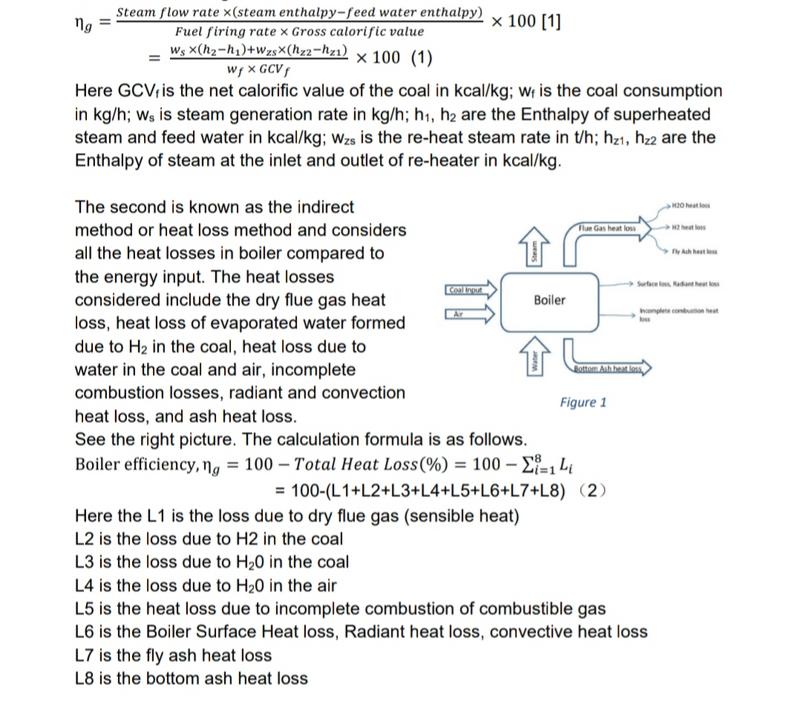

Direct method is obtained by the ratio of energy gain of working fluid (water or steam) compared to the energy input into the boiler. Here is the formula they used:

Comparative analysis of boiler efficiency

Comparative analysis of boiler efficiency

(1) Direct method

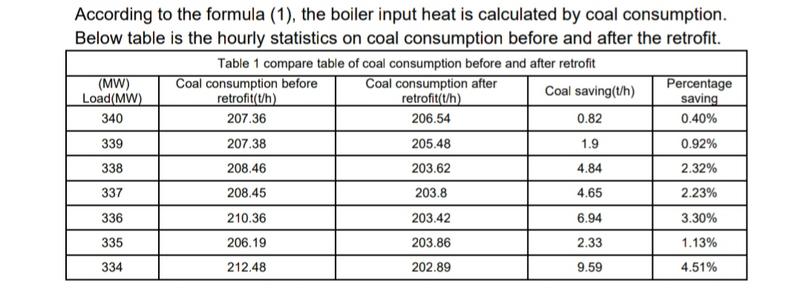

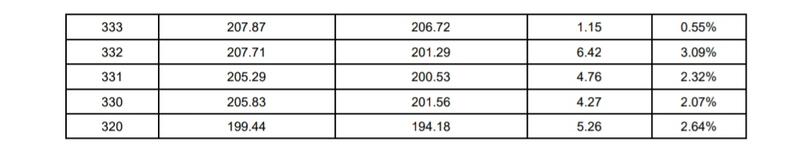

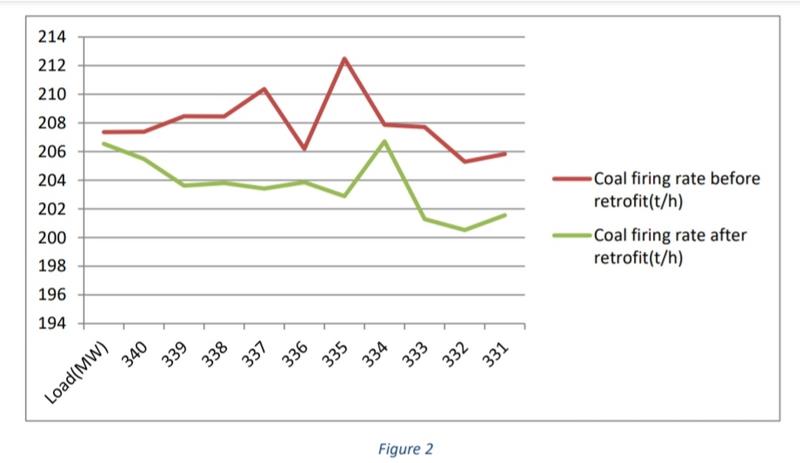

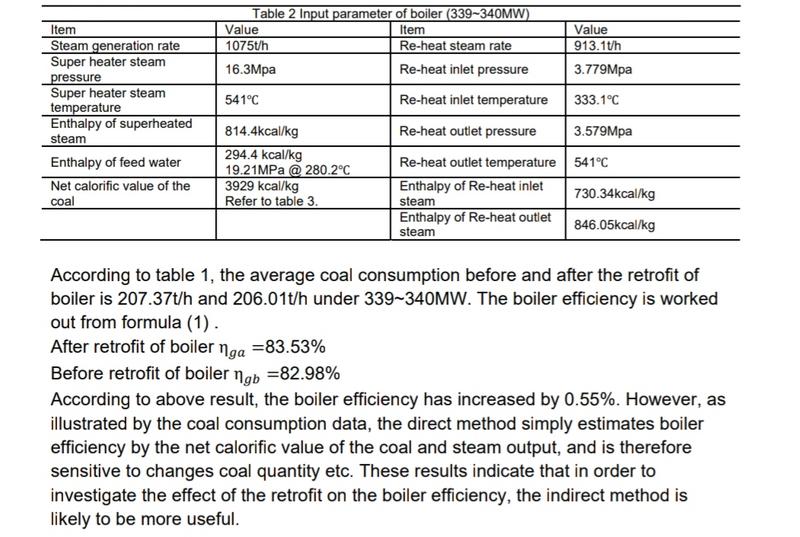

Based on Table 1 and Figure 2, that coal consumption has reduced by an average of 2.12% over a boiler load range of 320 MW to 340 MW since the retrofit conversion of Unit 2 to a Dry Bottom Ash System. Table 2 is the operating data from the owner with the boiler load between 339 and 340 MW which can be used to calculate the boiler efficiency using the ASME PTC4.1 direct method. [3]

Based on Table 1 and Figure 2, that coal consumption has reduced by an average of 2.12% over a boiler load range of 320 MW to 340 MW since the retrofit conversion of Unit 2 to a Dry Bottom Ash System. Table 2 is the operating data from the owner with the boiler load between 339 and 340 MW which can be used to calculate the boiler efficiency using the ASME PTC4.1 direct method. [3]

(2) Indirect Method

For the Indirect Method, the study explored the various factors in measuring the efficiency of the boiler system. These factors include:

a) dry flue gas heat loss

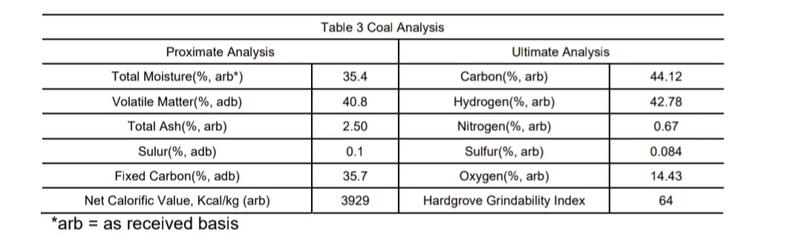

Dry flue gas heat loss is the main reason of boiler heat loss. Using formula (2), various heat losses are discussed here:

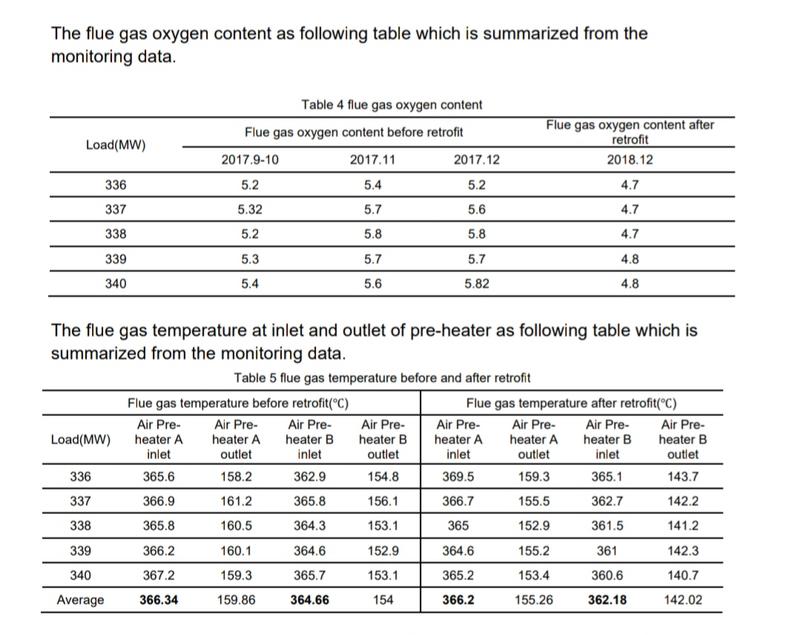

Based on this data, there is no significant change in the flue gas temperature at the inlet of air preheater, and the oxygen content decreases. With the help of the advanced air control DUNOCON system, “the cooling air quantity is controlled quantitatively to the maximum extent”, thus no excess air enters the boiler through dry bottom ash handling system. The other dry system has multiple air doors, but DUNOCON has only one air door on the head of the conveyor which is interlocked with the ash temperature of conveyor outlet. As an effect, “the cooling air quantity has been limited to maximum extent under the premise of ensuring the ash cool down effect”. [3] The DUNOCON also has a special penetration heat transfer design that improves the cooling efficiency and reduces the need for cooling the air. In addition, this helps the unburned carbon at the bottom ash re-burn and recovers its heat.

In this part of the study, the boiler efficiency is increased by 0.382%.

-----

Other factors under indirect method:

b) heat loss due to evaporation of water formed due to H2 in the coal,

c) heat loss due to H20 in the coal

d) heat loss due to H20 in the air

e) heat loss due to incomplete combustion of combustible gas

“The heat loss due to the incomplete combustion is principally concerned with the losses resulting from incomplete combustion of the gaseous products such as CO, H2 and various other hydrocarbons which can potentially be found in the flue gas of a boiler. Considering Mariveles Unit 2 is a large modern Utility Boiler, then we will assume that the losses through the incomplete combustion of gases is negligible for this study.” [3]

f) heat loss due to Boiler Surface Heat Loss, Radiant Heat Loss, and Convective Heat Loss

“This study assumes that the Boiler Surface Heat Loss and Convective Heat Loss will not be have been affected by the changes to the bottom ash system. However, due to the change from wet system to dry system, the radiant heat at the boiler throat is recovered back to the boiler by the cooling air.”

Based on their calculations, the boiler efficiency is increased by 0.11% because of the radiant heat recovered through the cooling air.

g) heat loss due to unburnt in fly ash

i) heat loss due to bottom ash in the wet system

All the bottom ash is cooled by the water. As a result, there is a loss of all the sensible heat associated with the bottom ash. In comparison, the dry system uses the cooling air to recover the bottom ash sensible heat and reintroduces it to the boiler. In addition, part of the unburned carbon in the ash can burned during the transportation process and the heat will be recovered by cooling air. Also those heat generated improves the boiler efficiency.

-----

Regarding the carbon combustion quantity during the conveying period, the study reported the following test list:

Carbon content in wet ash 4.59%

Carbon content in dry ash 3.5%

This shows that about 1.09% of the carbon in the dry bottom ash reburns and releases heat. Those heat is also brought back to the boiler by the cooling air. The unique penetrating cooling action of the DUNOCON system increases the contact area between the bottom ash and the cooling air, and increases the combustion probability of carbon. Qt=174876 KJ/hr From the formula (16), the boiler efficiency increase R2=0.016%. [3]

To sum up, the efficiency of the boiler is increase by 0.51% after the retrofit in indirect method.

Cost and energy conservation

a) From the table 1, the average coal consumption before and after the retrofit of boiler is 208t/h and 204.45t/h under 330~340MW. Assuming that the annual operating time of 8000h, the annual coal saving is about 28,400t. [3]

b) Comparing this with the wet bottom ash handling system, the dry system has no circulating water system, thus the system is simpler and the operation is fully automatic. Additionally, the power consumption of dry system is lower than wet system.

c) After the retrofit, the daily maintenance work of dry system is almost zero. Compared with the wet system, it saves a lot of labor cost for the power plant.

d) Studies show that for every 1% increase in boiler efficiency, 2% of carbon dioxide emissions can be reduced [5], so the dry system also contributes to the reduction of emissions.

In conclusion, based on the study and analysis, the Unit 2 boiler efficiency of GN Power Mariveles Plant increased about 0.51% after retrofit to DUNOCON dry bottom ash handling system. The reduction of flue gas quantity is the main reason to improve the boiler efficiency. The advanced air control technology of the DUNOCON system is an important key point. “The recovery of radiant heat from the boiler throat and sensible heat from the bottom ash also improves the boiler efficiency. The improvement of boiler efficiency saves about 28,400 t of coal for the power plant every year. And compared with wet system, dry bottom ash handling system is more advanced, safe and stable, and saves a lot of operating costs for the power plant.”

-----

Since the early 1990s, GNPower Ltd. Co. has been excelling in the power industry with their remarkable achievements in the completion of power projects. Their power plant projects had been providing electricity supply services to several Philippine-based customers. Other than developing coal-fired plant in Mariveles, (GNPower Mariveles Energy Center Ltd. Co.), they also have the GNPower Kauswagan Ltd. Co., and the upcoming GNPower Dinginin Ltd. Co. Of note, GNPower is the first Retail Electricity Supplier (RES) to be licensed by the Energy Regulatory Commission. They are also the first to have signed long-term power supply agreements with a group of Contestable Customers since 2006. GNPower also adheres to the mandate of the EPIRA Law of Department of Energy.

-----

Acknowledgement:

Mr Edgardo B. Cruz of Philippine Coal Plant Users Group and Mr Ariel Punzalan of PMR Group and GNPower Ltd. Co.

References:

[1] Retrieved from the company website of GNPower Ltd. Co. - https://www.gnpower.com.ph/about-us-new/

[2] Chavez, Leilani (Nov. 5, 2020). Mongabay News. "Philippines declares no new coal plants — but lets approved projects through".

[3] Boado, Artemio, Cruz, Edgardo B., et. al. “A Study of the Changes in Efficiency of a Coal Fired Boiler Following the Conversion to a Dry Bottom Ash Handling System”.