An Explorer’s Story By: Michelle Wright

A portable X-ray fluorescence (XRF) analyzer is a powerful tool to have in your mining and geochemistry field kit. One explorer uses three Vanta™ handheld XRF analyzers for copper-silver exploration in Peru. Todd Houlahan, Olympus' Director of International Mining, recently sat down with Lars Dahlenborg, President of Hannan Metals overcome challenges in exploration.

.png)

The San Martin Project: A Copper-Silver Target in a Dense Rainforest

The top challenge Hannan Metals faces in its copper-silver exploration projects is the terrain.

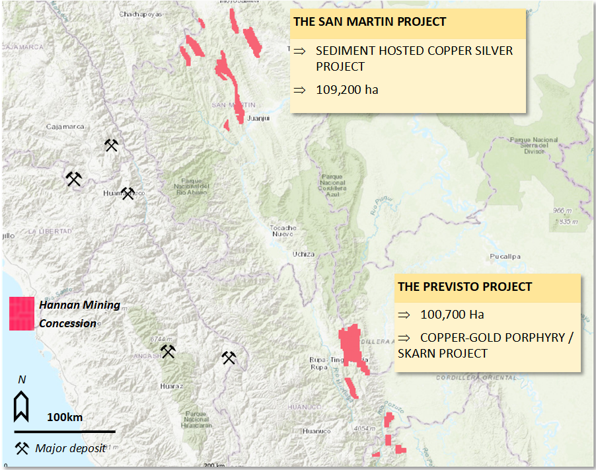

Hannan Metals’ San Martin project—a strata bound sediment-hosted copper-silver target—is in the Amazon foreland basin, eastern Peru.

This region shows evidence of a basin-wide mineralization system active over hundreds of kilometers. This area is difficult to access due to dense rainforest and steep slopes. To get to the nearest field site, geologists must walk 1–3 hours from the closest 4x4 road. Another challenge is the limited outcropping.

While prospecting creek and stream sediments are effective methods to reduce the search space in this terrain, the dense vegetation and lack of rock outcrops—less than 1%—make it difficult to prove the continuity of mineralization between outcrops. As a result, Hannan Metals needs to The San Martin Project perform systematic soil sampling and analysis to map mineralization under cover.

Faster Soil Sampling for Copper-Silver Mineralization:

Hannan Metals turned to Vanta handheld XRF for faster soil sampling. To test its analytical capabilities for the project, Hannan Metals compared the Vanta XRF data to the lab data from conventional soil sampling.

The results exceeded expectations:

- Excellent spatial correlation between the Vanta analyzer and lab data for copper (Cu)—the primary element of interest.

- The Vanta analyzer detected the same anomalies as the lab data in the same dynamic parts per million (ppm) range.

- Very good correlation with known outcrop mineralization.

Importantly, the Vanta analyzer produced fit-for-purpose data for key elements:

Pathfinder elements: copper (Cu), zinc (Zn), manganese (Mn), iron (Fe), arsenic (As), and nickel (Ni)

Major elements: potassium (K), calcium (Ca), magnesium (Mg), barium (Ba), silicon (Si), and titanium (Ti)

Establishing a Quality Control Program for the Copper-Silver Exploration Project:

All in all, the Vanta analyzer provides many benefits for the copper-silver project:

- 60% faster sampling rate enables the geologists to sample a larger area and increases the chance for discovery.

- Faster communication of results to management and other stakeholders.

- Enables real-time decisions during soil sampling—helpful for determining infill or extension of sample traverses

- Minimal sample size: reduces 800 kg of soil per month.

- Good value: payback time of one Vanta analyzer is about four months at the current sampling rate (this only accounts for hard assay costs—not the other logistical benefits).

To learn more: TRADERS INDUSTRIAL SUPPLY CO., INC. 24th Floor Trident Tower 312 Sen. Gil Puyat Ave., Makati City 1209 Philippines E: trisco@pldtdsl.net | 1980trisco@gmail.com T: +632 8817-9004 | +632 8844-0749