Thom Hanna, PG, Hydrologist and Technical Director for Johnson Screens, discusses key aspects of the Design and Ownership of wells for Managed Aquifer Recharge (MAR) and Aquifer Storage Recovery (ASR) projects.

As the natural aquifer replenishment process becomes too slow to cope with society’s growing groundwater demand, Managed Aquifer Recharge (MAR) and Aquifer Storage and Recovery (ASR) projects have become an important part of the long-term management of our hydric resources. Following that technique, water supply aquifers can be used for storage to mitigate water shortages and changes in wet and dry weather patterns.

During periods of water abundance, water can be stored in aquifers and later extracted in times of need, providing more water resilience. MAR is becoming an important practice for water management due to its minimal use of above-ground space and prevention of water loss by evaporation. With many years of proven performance supplying water in confined and unconfined aquifers, MAR applications can maintain operational standards at less than 1/3 of the footprint of traditional reservoir storage.

The design of wells used for MAR is similar to that of production wells. However, wells used for injection and extraction (Aquifer Storage and Recovery, ASR) require additional design considerations for their successful long-term operation. Inefficient wells used for MAR are more expensive to own and operate and require more maintenance, resulting in downtime.

One of the biggest challenges for MAR systems is efficiency losses due to clogging wells. Water quality needs to match that of the aquifer, and materials used in the construction of the well should include only those that do not increase the rate of clogging or geochemical reactions in the aquifer. Selected well equipment should resist corrosion to ensure that water chemistry and/or biological corrosion agents do not lead to aquifer degradation due to physical clogging or chemical reactions between aquifer water and materials. Additionally, carefully selecting filter pack size and material will improve production efficiency and bacteriological resistance.

Additionally, controlling the flow of recharge water requires careful consideration and selection to prevent cascading water from entraining air and pushing it into the well casing, bore, and aquifer. The entrained air can block water flow and is a source of oxygen that may increase corrosion and biofouling. As part of the flow control, pumps and motors require careful selection and application to allow for long-term reliability and adequate backflushing of the aquifer.

The design shall include instruments for measuring flow, water levels, and water temperature. Pump and motor data, including motor amperage, voltage, KW, KWH, and rotational speed, provide the means for calculating pump efficiency and energy usage and facilitate the calculation of wire-to-water overall efficiency. That data set should be stored and charted for study and comparison over time, providing well owners with means to optimize operations and maintenance.

Johnson Screens Provides Integrated Solutions for MAR/ASR Wells

MAR and ASR are among the most demanding applications in the Water Well industry and require comprehensive solutions to provide reliable wells while balancing expenses. By combining the tradition and knowledge with which we have led the Water Well industry for 120 years, Johnson Screens provides complete solutions designed specifically for these applications. These solutions are supported by technical and construction experience in some of the world’s most demanding projects, resulting in the most reliable equipment in the industry.

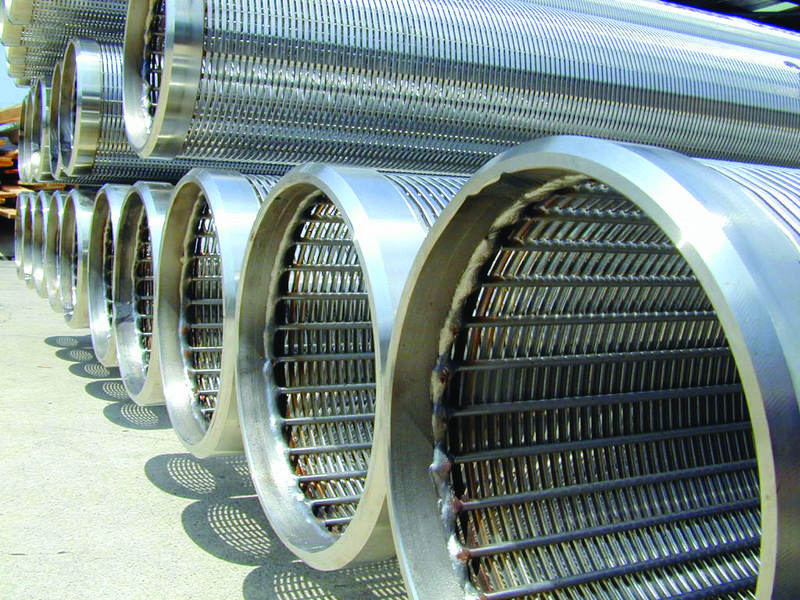

Our stainless-steel rod-based screens for water well applications rely on our signature Vee-Wire® construction to offer the highest open area to flow and lower energy requirements in both injection and production cycles. The continuous slot design promotes efficient sand control and lowers the entrance velocity of the water, reducing encrustation rates and plugging risk while preventing sand from damaging pumps. Lastly, the high open area also promotes better access to the entire formation around the screen, allowing fast and effective fines and drilling fluid removal, leading to better well development.

Johnson Screens’ Muni-PakTM Pre-Packed Screens eliminate the need for a larger borehole, shorten the time required to drill a well, and drastically speed development time. The Muni-Pak’s dual-screen construction is four times stronger than standard rod-based screens, allowing for more aggressive development and better resiliency to unexpected hole problems, continually driving down installation and operational costs.

Gravel packing is a common industry practice that introduces additional costs and considerations to well construction. Shur-PakTM Glass Beads are an upgrade from traditional filter packs for water wells. They are easier to install than conventional filter packs, chemically inert and eliminate bridging risks during installation. Shur-Pak is easy to handle and can be sized and installed using similar methods and techniques. International organizations also certified Shur-Pak to be used as a drinking water system component.

About Thom Hanna

Thomas “Thom” M. Hanna, PG, is Hydrologist and Technical Director for Johnson Screens with over 35 years of experience in well design, construction, rehabilitation, and development. His experiences include hydrogeologic investigations and the design and optimization of well efficiencies for mine dewatering and water supply investigations. Hanna has authored or co-authored many publications, including The Operational Stage of the Well, the third edition of Groundwater & Wells, and numerous technical papers. He has been an instructor and invited lecturer for many groundwater organizations and universities in different countries.

About Johnson Screens Water Well Solutions

Johnson Screens, a brand of Aqseptence Group, is the leading global provider of screening and auxiliary solutions. For 120 years, we have provided the innovation the Water Wells industry requires with the tradition customers want. Our complete portfolio of water well solutions include screens and casing, drop pipe, chemicals, filter packs and accessories.