The 80th Philippine Mining Club Luncheon in July featured two companies who underscored the importance of technology and expertise in achieving safety, sustainability, and environmental stewardship.

A Swiss Lab Urges Mining Companies to Comply with Carbon Reporting Directive

A pioneer in ISO certification in the Philippines and a global leader in lab testing, inspection, and verification, SGS Philippines Inc. takes the lead in helping mining companies comply with a new carbon accounting mandate.

Randall Evangelista, Business Manager, Industries & Environment – Health & Safety of SGS Philippines, Inc. was one of the guest speakers in Philippine Mining Club Luncheon on July 18, 2025. He is also a Greenhouse Gases Lead Auditor under GHG Protocol & ISO 14064-1:2018.

In his presentation titled “Sustainability: Facets of Carbon Accounting”, he urged mining firms to comply with the new carbon accounting directive.

As an environmental expert, Evangelista emphasized the importance of carbon accounting and greenhouse gas (GHG) reporting among Philippine industries, particularly the mining sector.

This is in reference to the DENR latest order, DAO 2025-10. The new regulation is in conformance with the United Nations Sustainable Development Goal (SDG) 13 on climate action.

More specifically, DENR Administrative Order 2021-43 requires companies to report their emissions. This order contains “Guidelines on the establishment of the carbon accounting, verification, and certification system (CAVCS) for forest carbon projects”.

It states, “Provides for establishing a carbon accounting, verification, and certification system for forest carbon projects to encourage and support investments in activities that sequester carbon dioxide and avoid emissions from deforestation and forest degradation”.

Evangelista pointed out that GHG reporting is now a key expectation from investors, customers, and regulators as part of risk management and business accountability. While full implementation in the Philippines remains gradual, the practice is steadily expanding in various industries, from mining to food production and infrastructure—where carbon emissions are being monitored and verified.

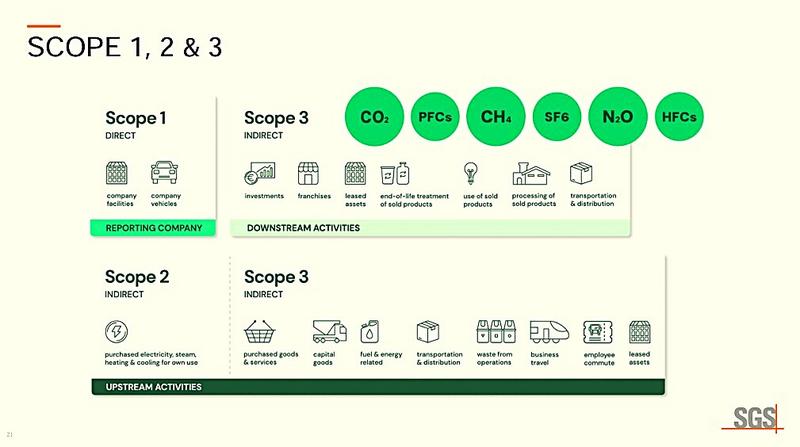

From his presentation, in Setting Operational Boundaries, it entails three steps, namely: identify emissions associated with operations, classify emissions as direct or indirect, and categorize the “scope” of emissions.

Carbon accounting and reporting in the Philippines follows international standards and methodologies, namely:

-- ISO 14064-1

-- GHG Protocol, A Corporate Accounting & reporting Standards

-- IPCC Guidelines for National Greenhouse Gas Inventory GHG Protocol http://www.ghgprotocol.org/

-- UK Government guidance

“Guidance on how to measure and report your greenhouse gas emissions” [1]

These guidelines cover both direct and indirect emissions under Scopes 1 and 2, with Scope 3 involving supply chain emissions. Mining companies were encouraged to begin measuring Scopes 1 and 2 to establish baseline data that can later guide reductions and sustainability strategies.

Mining firms have the opportunity to engage in carbon sequestration within their declared rehabilitation areas, primarily through the implementation of biomass or, more effectively, mangrove projects.

Through these initiatives, they can be converted into valuable carbon offsets and subsequently traded as carbon credits within established international frameworks, such as the VERRA protocol or the Verified Carbon Standard (VCS) Program. VCS is the world's most widely used greenhouse gas (GHG) crediting program.

The potential of mangrove ecosystems was emphasized by Evangelista, that the total carbon sequestered by mangroves is 20 times that of a regular forested area. Such projects, described as "low-cost, high-impact" strategies, present a pathway for the industry to contribute significantly to environmental protection.

SGS Philippines, Inc. offers both consulting and third-party verification services and is an accredited auditor under VERRA. The company has been operating in the Philippines since 1949, and is currently the country’s top provider of certification, testing, verification, and inspection.

Their Philippine headquarters is in Makati City, with a network of offices and laboratories located in Subic, Mariveles, Navotas, Batangas, Albay, Nueva Vizcaya, Masbate, Leyte, Surigao City, Davao City, and Cebu City. SGS was founded in Rouen, France, in 1878. Its headquarters moved to Geneva, Switzerland, in 1915, and it was officially renamed Société Générale de Surveillance (SGS) in 1919.

Konecranes: The Future of Material Handling

The next speaker for the Mining Luncheon is Steve Gagnuss, Vice President, Southeast Asia, Industrial Service & Equipment for Konecranes. He has 39 years of experience in Konecranes. His presentation is titled “Safe, Productive and Sustainable Products and Services in the Mining Industry”.

Konecranes is a global leader in material handling solutions, serving a broad range of customers across multiple industries. The company is known to consistently set the industry benchmark, from everyday improvements to the breakthroughs.

Steve Gagnuss, Vice President of Konecranes

During his presentation, Gagnuss emphasized the company’s strong commitment to safety, sustainability, and digital innovation in lifting solutions.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports, and terminals.

He also highlighted the company’s global operations and technological advancements. Gagnuss noted that many specifications in the industry remain outdated, limiting opportunities to integrate modern safety and productivity features. He urged customers to adopt updated standards that would allow the use of advanced technologies designed to enhance operational efficiency and workplace safety.

The legacy of Konecranes dates back in 1910 in Helsinki, Finland as KONE Corporation, an electrical motor repair shop. Today, the company operates in 50 countries with over 16,700 employees, and continues to lead in safety management, requiring employees to document observations and improvements through a mobile app. This practice helps drive operational enhancements both within Konecranes and its client operations. With the acquisition of the Demag brand in 2017, Konecranes now holds a Gold rating in sustainability, placing it among the top 5% of global companies for responsible operations.

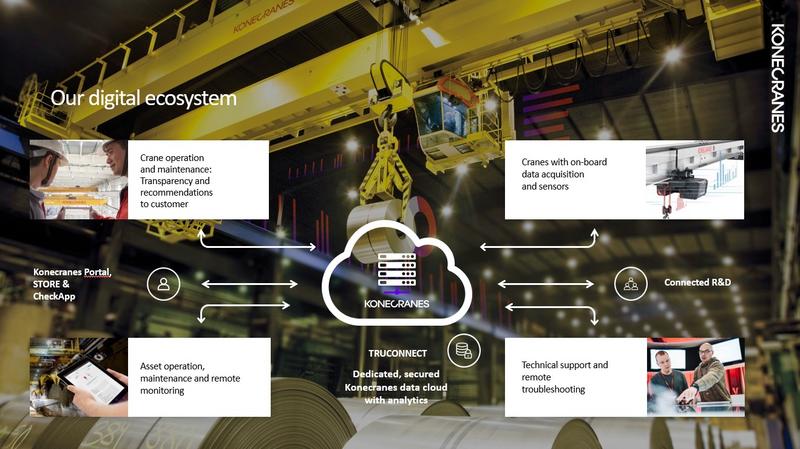

Konecranes currently has more than 17,000 connected equipment units worldwide, enabling real-time data monitoring through its Industrial Internet ecosystem. The company’s innovations, such as sway control technology that prevents load swing accidents, demonstrate its commitment to safety-driven engineering. Locally, Konecranes is set to deliver two large mobile harbor cranes to Cebu, showcasing its role in supporting port operations in the Philippines. With predictive maintenance tools, smart features, and digital transparency, Konecranes continues to redefine lifting as a safer, smarter, and more sustainable industry.

---

Photo credit: Marcelle P. Villegas

---

Reference:

[1] You may get a copy of UK Government guidance – “Guidance on how to measure and report your greenhouse gas emissions” from this link:

https://www.gov.uk/government/publications/guidance-on-how-to-measure-and-report-your-greenhouse-gas-emissions