The Philippine mining and quarrying industry is central to the country’s infrastructure and manufacturing sectors, providing raw materials for construction, power generation, and industrial applications.

However, mining operations face constant challenges—abrasion, corrosion, chemical attack, and equipment deterioration—all of which reduce productivity and increase operational costs.

Belzona, a global leader in polymeric repair and protection systems, has been working with the mining sector since the 1950s. Its cold-curing composite materials and protective coatings are designed to extend the life of critical assets while minimizing downtime. For Philippine mining companies, these solutions present an opportunity to improve safety, efficiency, and profitability.

Combating Abrasion in Grinding and Material Handling

One of the greatest challenges in mining is abrasion, caused by the constant movement of hard materials through crushers, mills, hoppers, and chutes. Traditional repair methods often require hot work, welding, or costly replacement. Belzona’s abrasion-resistant ceramic composites provide in-situ, cold-applied protection that minimizes downtime while extending service life.

For example, grinding mills—including liners, trunnions, and trommel screens—are prone to rapid wear. Belzona systems rebuild worn surfaces and create durable linings that withstand impact and erosion. Similarly, transfer points such as hoppers and chutes benefit from Belzona’s abrasion-resistant linings, which use alumina tiles and epoxy polymers to handle aggressive ore flow (see Figure 1).

Conveyor Belt and Elastomer Repairs

Conveyor systems, essential for transporting ore and aggregates, are exposed to constant wear, tears, and slippages. Belzona’s elastomeric repair materials restore ripped belts and damaged rollers without dismantling equipment, saving both time and money. The company’s positive grip solutions improve roller performance, reducing belt slippage and enhancing operational reliability (see Figure 2).

In addition, Belzona elastomers extend the life of heavy-duty tires and slurry pumps, reducing waste and preventing unplanned shutdowns. By providing flexible yet durable repairs, these solutions reduce the need for costly replacement parts.

Protection Against Chemical Attack

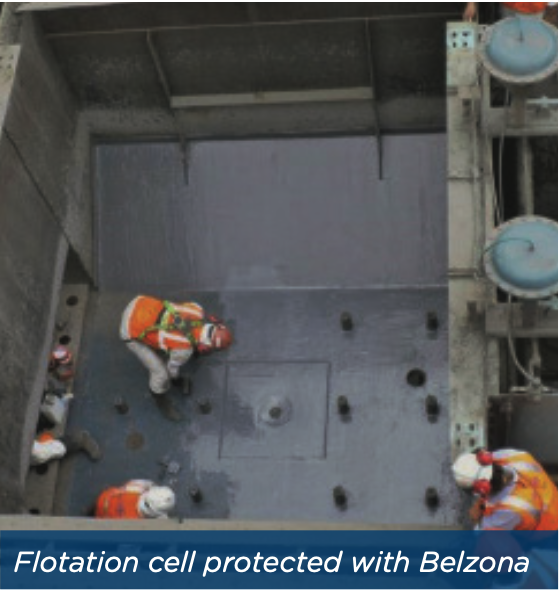

Ore processing plants in the Philippines frequently operate under harsh chemical conditions, especially during flotation, thickening, and solvent extraction processes. Belzona’s magma polymer coatings provide long-term protection against highly aggressive substances, including sulfuric acid, caustics, and other corrosive chemicals.

Flotation cells, SX/EW tankhouses, thickeners, and containment areas can all be lined with Belzona systems, creating seamless barriers that resist both corrosion and abrasion. This protection not only extends equipment life but also minimizes environmental risks from leaks and spills (see Figure 3).

Local Support, Global Expertise

Belzona products are supported by a worldwide network of over 140 distributors in more than 120 countries. In the Philippines, Wise Industrial Systems, Inc. provides mining companies access to both high-performance materials and trained technical consultants who provide specifications, application, and on-site support.

By addressing abrasion, corrosion, and chemical attack, Belzona helps Philippine mining companies safeguard their assets, reduce downtime, and ensure operational continuity. As the industry continues to play a vital role in the nation’s economic growth, adopting innovative repair and protection technologies will be key to sustaining long-term success.