Coal trading is a very competitive landscape. While end customers buy the quality of coal based on what is compatible with their boilers and furnaces, the traders need to be vigilant in sourcing and supplying right grades. Buyers impose price discounts if the coal’s calorific value and other key parameters fall short of expected values. To secure the contracted revenue and avoid any discounts, exporters typically tend to supply higher grades than necessary. This in turn eats into their profit and erodes margins.

Price penalties are also put in place if exports exceed the specific amount of moisture in the coal, since the moisture adds to transportation costs. Not to mention that since exports are typically global and long distance, breach of moisture limits can pose stability issues to the ships. In the worst-case scenario, such shipments at the port could even be rejected.

In this article we share the idea about how coal mining companies, traders, and end-customers can achieve a "happy buyer-happy seller" agreement.

Benefits

Coal Mining:

- Ash, ash composition, Sulphur, total moisture, and calorific value are critical information to decide value of the coal

- Avoid penalties by meeting the contractual specifications of the coal

- Bring down the production cost and improve yield

- Grade-wise stockpiling of the coal and

- Perfect blending in accordance with end customer specifications

Coal Plant:

- Incoming check of grades to verify specifications

- Verification of consistency or intrinsic deviation of the whole lot of material

- Optimization of coal yard management

- Blending of coal to target quality

- Optimize waste by safe use of low cost / low quality coal

- Bunker feed control in power plants

- Optimization of combustion parameters for boilers

- Assurance of optimal running conditions of boilers

- Minimize slagging and clinkerisation of ash in the boilers

- Reduced maintenance costs through minimal derating and boiler outages

About CNA Coal

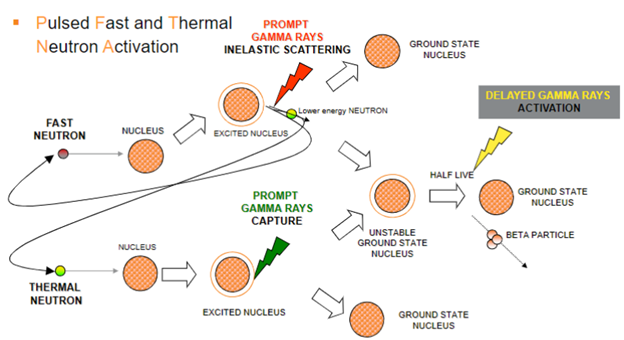

CNA Coal has been designed for tough environments of mines, featuring the cutting-edge Sodern neutron technology with unmatched lifetime and stable neutron output (D-T PFTNA).

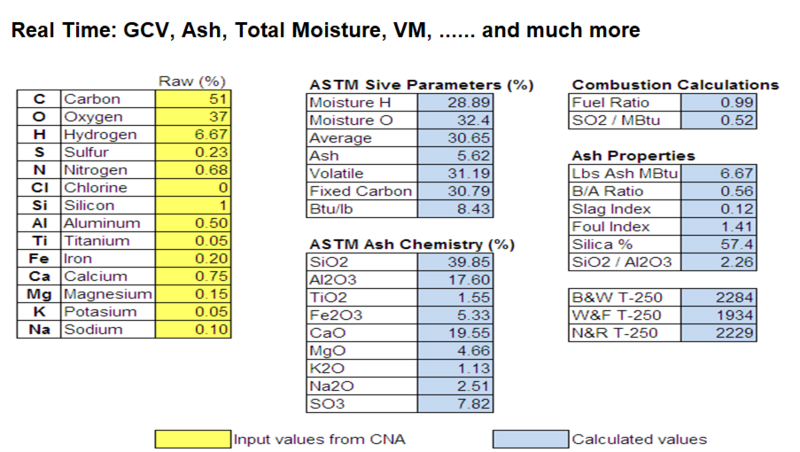

Coal is an important industrial mineral both as a fuel and feedstock. Coal quality can vary greatly depending on the source. Hence the usage and price are highly dependent on the composition. Whether located directly at a mine, a coal processing plant, a metallurgical plant, power plant or other usage point, the CNA can provide reliable real-time information on the coal composition, calorific value, ash content, volatile matter, and total moisture. The CNA with unique neutron generator technology enables measurement of a wide range of elements, including C and O.

Features/Benefits

- Get Real-time Analysis

- Proven On-Off electric neutron source

- Achieve High Intensity and performance on results

- Analyze all the elements of your interest, including C and O

- Enjoy Up-time and Savings with Long Term Availability of Neutron Source

- No need for frequent re-calibrations

- Automatic radiation protection system (ARPS) for unrivaled safety during operation and maintenance

- Fits wide ranging belt dimensions starting 600mm to 2200mm and beyond

Examples of Analysis in Coal

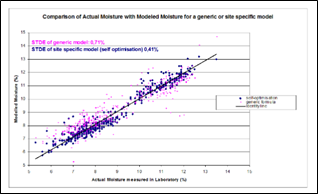

Moisture

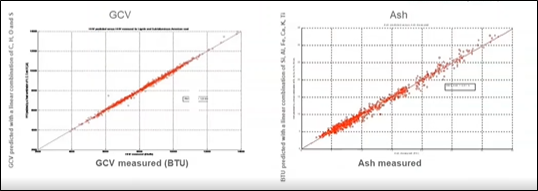

Ash and GCV

Conclusion

CNA Coal provides a powerful online monitoring tool using the D-T Pulsed Fast Thermal Neutron Activation (PFTNA). This makes it the only tool to provide ultimate and proximate analysis of coal in real time. The CNA helps provide coal of specific ash, calorific value, moisture; not more, not less…. exact!

CNA real time analyzers with unique D-T PFTNA technique are also available for elemental analysis of other ores and minerals viz. nickel, iron, bauxite, copper and lime.