X-ray diffraction (XRD) is the only laboratory technique that reveals structural information, such as chemical composition, crystal structure, crystallite size, strain, preferred orientation and layer thickness. Materials researchers, therefore, use XRD to analyze a wide range of materials, from powder X-ray diffraction (XRPD) to solids, thin films and nanomaterials. Mining by using XRD has been critical for ores exploration, path-finding minerals, process optimization and final product. One of the application is geometallurgy became more and more important during the separation of ore and waste material to cope with changes in raw material composition and to run the process under optimal conditions. Therefore, mineralogical analysis and the direct monitoring of process parameters (such as the acid consumption) became an essential method to monitor process conditions.

Ultimately, the goal is to obtain a good XRD pattern result with clear, sharp peaks with low background noise. Good data collection is so critical towards the next phase, which is data analysis and interpretation. These impact how you draw implications and determine your next steps in terms of your materials research and also process monitoring whether in pharmaceuticals, mining geology, catalysts or specialty chemicals. Earlier, our senior application specialist, Dr. Uwe Konig, Mining and Metals Business Development Manager, discussed the basics to powder X-ray diffraction and its application in mining topics. During the webinar, he covered the basics:

Interview to Uwe Konig, Business Development in Mining and Metals.

Introduction to Powder XRD

Could you please summarize the meaning of the peak intensity and peak position in the XRD pattern?

Uwe: Peak position refers to the maxima of intensity around the theoretical Bragg angle and value of this maxima is referred to as peak intensity.

XRD patterns: how do they vary from crystal structures

Uwe: Difference in crystal structure affect position of diffraction peaks. Hence two substances having different crystal structures will produce different sets of XRD scans.

XRD Software

How can I quantify the different phases or different composition? Please shed some more light on this.

Uwe: A position of the peak comes from the dimension of unit cell, an intensity coming from how many electrons are present and where they are. So, everything can be easily calculated in software. So, once we found out what phases are present in the sample (mixture), because we already know the positions of the peaks, we just need to minimize a difference between observed intensities and calculated intensities by cycling fitting procedures until we get a reliable results.

What if we cannot find the crystal structure in ICDD?

Uwe: It means that nobody has published that material yet. So, you need to solve the structure by yourselves. And publish it!

Is there any software to adjust the peak ?

Uwe: HighScore and HighScore Plus is the software by Malvern Panalytical. It can be used to analyze XRD patterns from other brands of X-ray diffractometers.

XRD Technique

In the diffractogram of amorphous materials, such as SiO2, it is common to see an amorphous halo between 20º and 30º. Will this also be observed for example in a nanostructured SiO2 matrix coating?

Uwe: Yes, it does. But, as you said the thickness of SiO2 is in nanoscale, this would not be seen when you use normal Bragg Brentano geometry. I recommend you use parallel geometry which keeps the incident angle at 1~2 degrees and scan only 2 theta(detector). So, you can effectively observe the diffractogram from the surface(skin) of the film.

Does destructive interference caused by element position reduce only the intensity or cause peak shift?

Uwe: Only reduces the intensity. A peak shift can be caused by the size of unit cell.

How to remove the substrate peaks while measuring?

Uwe: If you used a single crystalline material as substrate, you could tilt your sample a little bit (around 1 ~ 2 deg) during the sample prep. Then you will not see any peaks from the single crystal substrate.

If we use composite materials like brake pad applications, do we need to use spinning method for better accuracy results? your view please?

Uwe: It depends on how small your particle is. But I would say that spinning is always beneficial on polycrystalline material!

How does soller slit affect Inorganic crystalline nanomaterials?

Uwe: When smaller soller slit are used, we achieve better resolution at the cost of intensity.

Sample Preparation

Regarding on sample preparation for powder samples. You mentioned about smearing a sample, how do you do that?

Uwe: You can prepare some plate having a rough surface like sandpaper. Then you can put the plate onto the sample and slide a little bit to smear the pressed powder.

Talking about materials such as soil cuttings, what could be the impact of chemicals that would have encapsulated/absorbed onto the structure?

Uwe: I am not sure what is the detailed situation, but in any cases, materials can be encapsulated or absorbed onto the surface of the matter under high temperature or pressure. Probably, some triggers were there to make secondary phases on the surface.

What’s the optimum particle size of the sample for getting accurate results?

Uwe: Theoretically 1-micron meter is the best. But I could say below 20 um is good enough if you spin the sample!

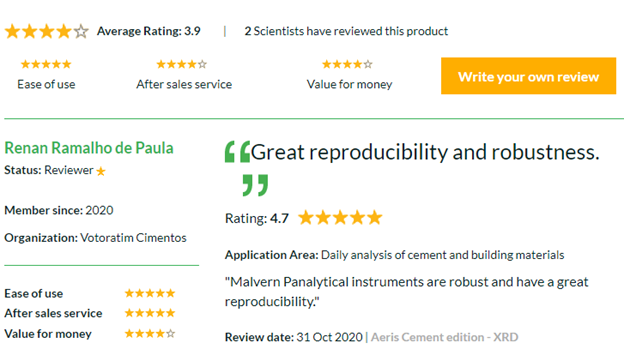

See below review for Aeris XRD;

How XRD improved mineral analysis for lithium ores?

Uwe: This Lithium ores are easy to quantify by XRD. All types of Sample such as petalite, lepidolite etc mostly XRD can do.

Interested to improve in your XRD data analysis and applications? Join our free series of webinars:

- Introduction to powder X-ray diffraction. View on-demand

- Studying battery cathode materials using X-ray diffraction View on demand

- Expand your powder XRD applications for materials characterization research View on-demand

- Knowing the difference between good and bad data: XRD data analysis – View on-demand

- Improving your phase search mapping by defining your elemental range: introduction to elemental analysis using X-ray fluorescence. View on-demand

- Range of XRD instruments to aid materials characterization research. View on-demand

Know More: https://bit.ly/3KdEBzh