Olympus’ X-ray fluorescence (XRF) analyzers provide high-performance, real-time geochemical data for rapid multielement characterization of soil, rocks, and ores.

Recent advances in XRF technology have increased the number of elements measured, improved the limits of detection, and reduced analysis test times.

Vanta™ XRF analyzers provide convenient and rapid measurement of many types of samples associated with Au exploration, within Au mines, Au mine labs, and refined Au products.

Benefits

- Rapid indication of potential Au mineralization through XRF analysis of pathfinder elements in soil, drill cuttings, and drill cores

- Priority sample selection, maximization of analytical budgets, and improved drill target generation by prescreening samples with XRF

- Improved ore deposit understanding, modelling, and vectoring with less dilution and better Au recovery via XRF mapping of structural features and identification of mineralized and altered zones

- Inexpensive and rapid rock typing by using XRF for lithogeochemistry

Source: Reflex Geochemistry

Pathfinder and Alteration Geochemistry

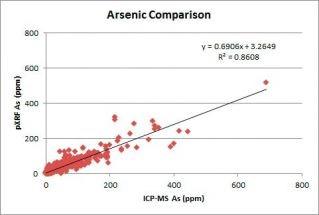

Most Au deposits have an associated geochemical signature (as shown in the table above). The XRF analyzer can detect these geochemical signatures, enabling geologists to better understand the geological system in which they are working. Typical Au pathfinder elements include As, Cu, Pb, Zn, Sb, Bi, Ag, and W.

Typical XRF LODs for Common Au Pathfinder Elements with Vanta VMR GeoChem Model

XRF Analyzer for the Detection of Gold

It is common knowledge that handheld XRF analyzers do not support direct low level measurement of Au in geological samples (e.g., low ppm and ppb). The lab-based fire assay technique is commonly recognized as the method of choice for Au analysis. Au L-level X-ray lines are located in a very crowded area of the X-ray fluorescence energy spectrum. In this part of the spectrum, interference from other elements (e.g., As, Zn, W, and Se) can yield a false-positive Au determination.

Direct measurement of Au by XRF can be achieved in specific cases such as high-grade (> 5 ppm) quartz vein environments (relatively interference free) or within refined Au products (where Au is present in very high concentrations).

An increasing number of Au onsite mining laboratories are using XRF in place of, and as a supplement to, fire assays methods. Please refer to the Olympus Application Note “Use of Handheld XRF in Au Mine Laboratories.” Mines are also using Olympus handheld XRF analyzers for measuring Au in activated carbon. Please refer to the Olympus application note, "Measuring Gold in Activated Carbon."

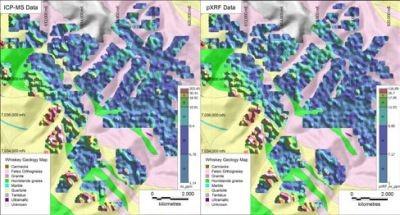

Contor plots of As, Cu, and Pb in surface soil using field XRF compared with ICP analysis from Au exploration project in Canada.