Article by Engr. Jeffrey Q. Geronimo

In the recently concluded 2021 Prospectors and Developers Association of Canada (PDAC) convention, global leaders in mining have all agreed that the key to reduce risks and create more value in mining is by testing everything in the “virtual world” first. This is particularly done by taking risks, failing, and learning from mistakes -- not just digitally but also virtually.

DIGITAL TWIN VS VIRTUAL TWIN

“Digital twin” is not a new concept to the mining sector as computer-aided programs such as 3D CAD models have already been existent and utilized for several decades. However, while we have experienced vast improvements and upgrades, these models are still isolated from the real world and remains to be just digital models.

This is where the concept of “Virtual twin” experiences come into play. It is a great leap beyond the digital twin experience wherein more accurate and scientific real-world models are taken into consideration such as time, environment, and behaviors in varying conditions and scenarios. This will enable problems and solutions of the company to be communicated faster to different teams across the mining value chain -- thereby increasing the company’s understanding, collaboration and participation.

TAKING THE GREAT LEAP

Mining companies may already have the fundamental data, processes, and infrastructure they need to begin the shift. What they may be lacking is the state-of-the art connectivity, contextualization, and collaborative platform that will integrate all of its people, processes and data. This will be their portal to the virtual twin experience. This is where the GEOVIA Mining Intelligence suite powered by the 3DEXPERIENCE Platform may bridge the gap. It provides users with an overall view of their mining operations with ultra-fast access to information on top of easy and sophisticated analysis.

THE INTELLIGENCE NEEDED BY A SMART MINE

The 3DEXPERIENCE Platform connects GEOVIA users with role-based applications to connect people, ideas, data and solutions in real-time. It enables centralized control and viewing of mine data, providing a single source of truth on your business operations. Moreover, it allows efficient collaboration with traceability across the mining value chain

The GEOVIA Mining Intelligence suite, consisting of Production Intelligence and Geology Intelligence functions, extends the promise and collaborative power of the 3DEXPERIENCE platform by allowing users to reveal, measure and analyze mining data so that they may deeply understand and improve mining operations.

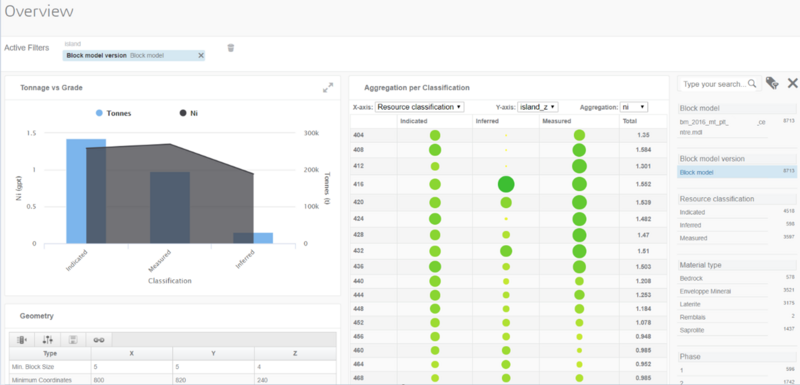

GEOLOGY INTELLIGENCE

“Geology Intelligence” is part of the Mining Intelligence offering. By simple configuration, it can show block model data in a graphical and tabular format. In addition, it gives emphasis on important information by using graphical techniques and drilldown into information to see more detail. Moreover, it analyzes these geological data and plot these as a chart.

PRODUCTION INTELLIGENCE

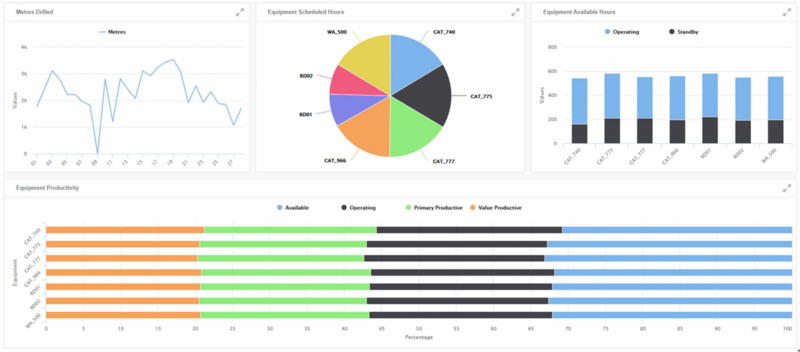

Monitor equipment performance: Many mining companies measure their equipment performance metrics through spreadsheets and creating charts manually. While it gets the job done, this tedious process does not easily permit detailed analysis or comparison with historical performance to aid decision making. With the “Production Intelligence” function bundled with the GEOVIA Mining Intelligence suite, equipment performance metrics can now be configured around the mine’s specific Time Allocation Model that enables detailed analysis of Equipment Performance.

Monitor production actuals against targets: GEOVIA Mining Intelligence aggregates collected data into a more manageable visual representation that assists in making decisions. This will improve business performance and increase profitability. The proprietary 3DEXPERIENCE platform reporting technology uses index files to ensure very quick and responsive reporting.

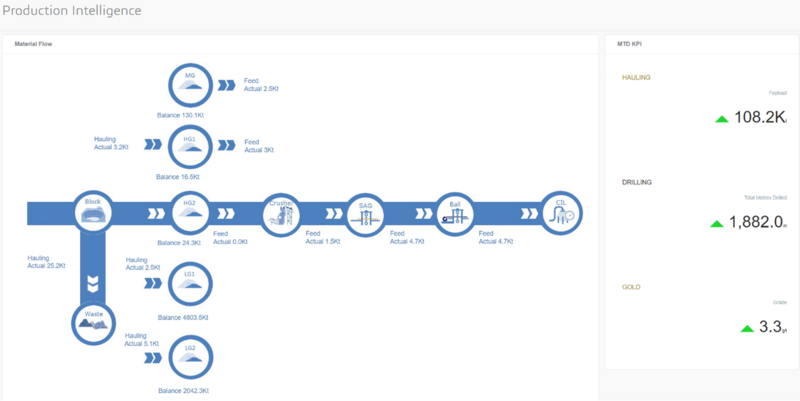

Production KPI and material flow key performance indicators: With a single glance, material flow and KPIs can now be aggregated and presented for an overall view of the mining operation. This is not exclusive to production departments as any other data related to the mine operation such as the mill plant may be displayed. Mine and Mill Plant data are generally always separated from each other due to their information differences. However, with Production Intelligence, it bridges that gap.

MINING SMARTER TOWARDS SUSTAINABILITY

As a step towards virtual twins, we enable a more sustainable mining environment by making it possible to do unlimited iterations, better operational insights, and greater flexibility. It simulates all these value-added services to model complex systems -- making it easier to analyze, test causes-and-effects, and significantly reduce risks faced by mining operations. Let Paramina Earth Technologies, Inc. be your partner towards your virtual twin experience journey. Contact us at paramina_solutions@paramina.com or reach us through our website www.paramina.com for more information.