Part 1: Defining Objectives, Stope Optimization, Stability Analysis and Schedule

By Engr. Mae Ann R. Cabasag

In today's mining industry, meeting market demand while ensuring sustainable extraction of Earth's resources is paramount. Given that market forces and changing conditions can greatly affect a mining company’s ability to meet market demand, mining companies need to be more agile and come up with robust mine plans. Digital transformation that encompasses strategic planning, optimization, analysis and scheduling is an effective enabler for this. Such a digital transformation is possible with Dassault Systèmes' Strategic Mine Planning Solutions. In this article, we will explore a transformational journey for an underground mine.

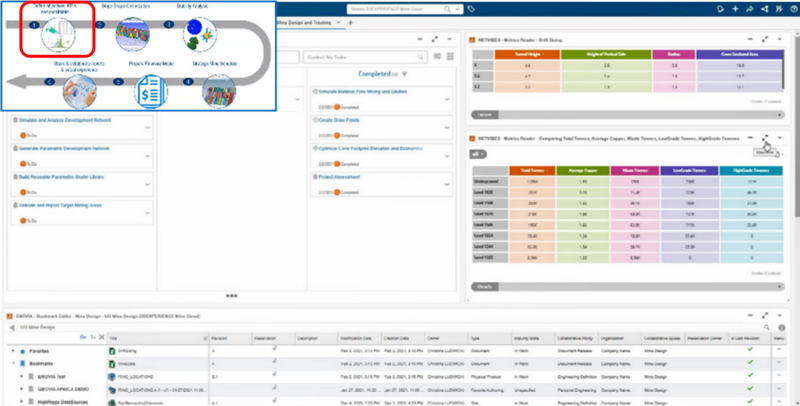

As shown, this digital transformation is made up of six processes. It begins by assessing a potential or active project, leveraging up-to-date resource data as its basis. These processes are navigated with the end goal of arriving at a strategic mine plan or an updated Life-Of-Mine plan— which forms the linchpin for vital decisions, including feasibility studies and project viability assessments.

The first process is DEFINING OBJECTIVES, KPI’s and CONSTRAINTS. In this process, data is centralized within the 3DExperience Platform, enabling seamless integration and interpretation of information from various sources to precisely define key parameters. This includes updating predicted development, production rates, and historical data to establish mining parameters for stope optimization and scheduling. It also involves creating a probability distribution for modeling uncertainties in uncontrolled variables within the solution set. Furthermore, the 3DExperience Platform can be utilized to gather real-time information from the internet, including emerging market trends, political developments, and metal price forecasts.

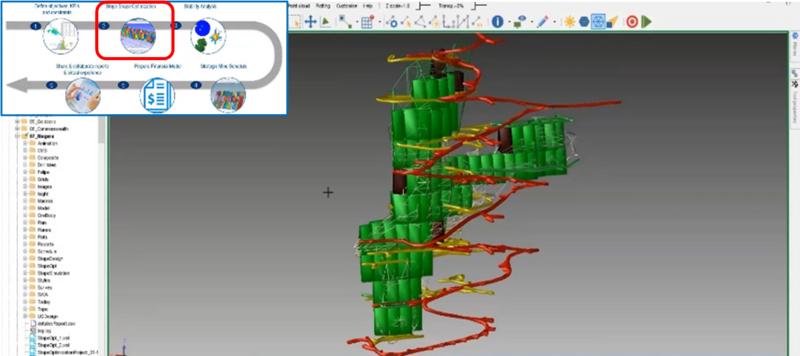

The second process is STOPE SHAPE OPTIMIZATION, which is a vital step in mining operations. DS GEOVIA Surpac’s Stope Optimizer (SSO) is employed to create optimal stope designs based on project objectives and operational constraints. Multiple scenarios are evaluated against key performance indicators (KPIs) to identify potential stope configurations. With the SSO connected to the platform, the Process Composer application is applied, allowing for various stope configurations to be explored, with iteration performed over multiple scenarios. This involves adjusting key design criteria such as angles, dimensions, cutoff grades, and pillar widths. The Monte Carlo Algorithm is also employed to ensure that uncertainty regarding economic parameters such as mining cost, processing cost, and current metal price is simulated and considered. Results are then analyzed using Analytic Tools to assess the impact of different inputs and to meet profitability requirements. This process step enhances stope value, task transparency, reproducibility, and significant time savings in generating and analyzing scenarios, ultimately resulting in a robust stope design that streamlines mining operations.

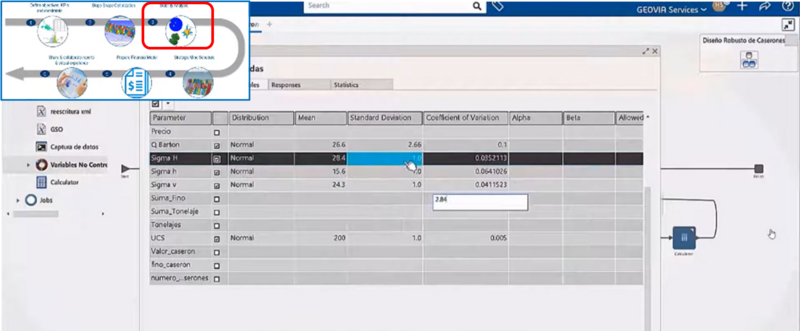

The third process is STABILITY ANALYSIS. Stability evaluation is performed on potential stope designs generated in the previous process. In this process, Process Composer simulation tool is also utilized to continue analysis of potential stope designs. However, instead of economic parameters, focus is on stability parameters such as geomechanical variables. As with economic parameters, these stability parameters, like H Barton, three sigmas and UCS, also come with inherent uncertainty, and Monte Carlo algorithm is used to model these uncertainties and explore various potential values. The Results Analytics application is employed to evaluate parameters, facilitate the ranking of stable solutions, and save simulation results to the Platform. This process enhances decision reliability, leading to safer stope designs, and significantly streamlines scenario analysis while reducing design rework. The selected stope configuration excels in economic performance and operational viability, forming the basis for downstream scheduling.

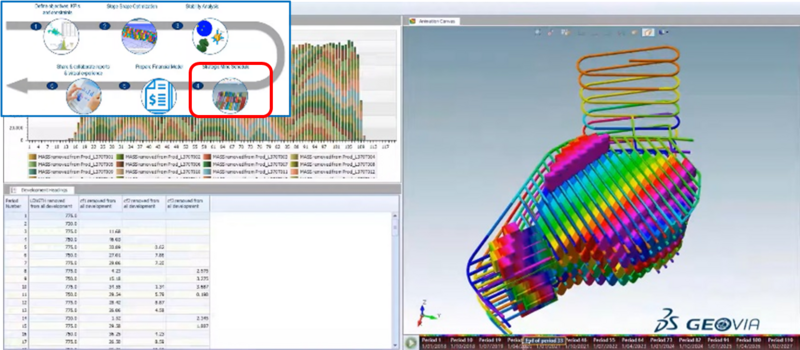

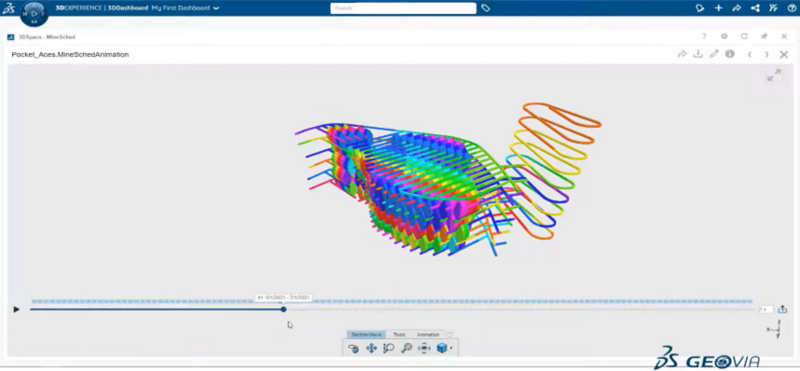

The fourth process is STRATEGIC MINE SCHEDULE. It starts with the 3D design of a development network needed to access the stope designs created in the previous process. This process involves scheduling development, production, and auxiliary activities, like backfilling, by setting up resources and defining an extraction plan with priorities and precedences. The goal is to analyze different sequences and production rates to determine an optimal schedule that achieves grade and material processing goals. Key schedule outputs, including cost, development meters, grade, and tonnage, are reported. Surpac is connected to the 3DExperience Platform, enabling access to stope designs, development networks, and block models. With Surpac, the development network, ramps, shafts, and ventilation raises are created. Then Minesched is used to create the underground mine schedule. The Mineshed dashboard provides tools for monitoring schedule progress: animations and Gantt charts. Integration with Process Composer allows for iterating different production rates and mining sequences, saving time, and aiding in exploring alternative options and what-if scenarios. The visualization capabilities of Mineshed and the 3DExperience Platform enhance the understanding of underground mining sequences.

In Part 2 of this article, we will discuss the remaining processes in UG Mining Digital Transformation: Preparing Financial Models and Sharing and Collaborating on Reports. Discover how these underground mining solutions combine to create a powerful end-to-end simulation, governance, and collaboration system. To learn more about the latest innovations and solutions in underground mining, get in touch with Dassault Systèmes' Value Solutions Partner, Paramina Earth Technologies Inc.

References:

Dassault Systèmes. Strategic Mine Planning for Underground. 3DS EVENTS. https://events.3ds.com/strategic-mine-planning-for-underground

Strategic Mine Planning in Changing Times. Dassault Systèmes. https://discover.3ds.com/strategic-mine-planning

A guide to GEOVIA Stope Optimizer in Surpac. 3DS Blog. https://blog.3ds.com/brands/geovia/a-guide-to-geovia-stope-optimizer/

The quest for the best plan in Strategic Mine Planning. 3DS Blog. https://blog.3ds.com/brands/geovia/the-quest-for-the-best-plan-in-strategic-mine-planning/