By Todd Houlahan

Advances in robotics are leading to faster and more efficient X-ray fluorescence (XRF) analyses for geo-exploration projects. One new robotics innovation revolutionizing XRF analysis is GERDA, the automated Geochemical Research and Documentation Assistant.

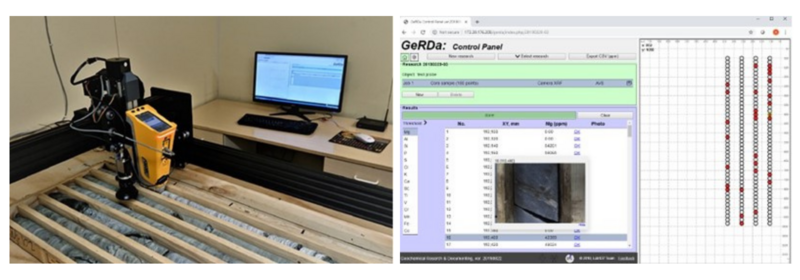

Created by the MEFFA Lab Oy in Finland, the automated unit is designed to test core in core boxes and soil, sediment, and crushed rock in plastics bags to achieve higher sample throughput with your portable XRF analyzer. The system is set up on a CNC table with a Vanta™ handheld XRF analyzer, a high-resolution USB camera, a simple control module based on Raspberry Pi 3, and easy-to-use software for visualization of results and data processing.

In parallel with GERDA, the inventors have started to develop a unique method known as Nugget Effect Gold Assay (NEFFA) to estimate gold mineralization in samples (typically crushed rock or crushed drill core).

Read on to learn more!

Developing the GERDA System

The GERDA system was developed by a team that has been using portable XRF analyzers on mineral exploration projects for over 15 years.

Largely focused on the use of pathfinder elements as part of their gold exploration projects, the inventors have witnessed the development of portable XRF analyzers over time, particularly the improvements in speed and the reduction in the test times required to achieve the levels of precision needed. They have also observed Olympus’ developments in detector technology and signal processing and, in particular, the Vanta analyzer’s ability to achieve lower limits of detection (LODs) of elements, including gold (Au).

As junior explorers on a limited budget, their focus has been on greenfield exploration, rapid identification of anomalies, generation of drill targets, and potential new discoveries, not resource definition. Key to this has been their ability to test a far greater number of samples using their portable XRF analyzers than would be possible if all samples were assayed in the lab. GERDA is critical to their ability to do this.

GERDA is designed to:

- Increase sample throughput for existing portable XRF owners

- Help select samples for more expensive laboratory assay

- Provide faster access to meaningful results for real-time follow up/infill

- Reduce the overall cost of exploration analytical budgets

- Make exploration programs more efficient

To see how GERDA works with portable XRF, watch this quick video:

https://www.youtube.com/watch?v=3-Gesp0Gjpk

What is Nugget Effect Gold Assay (NEFFA)?

To understand this new technique, it is important to know how the “nugget effect” works.

The nugget effect is a term used to describe the sampling problem that can occur when there are large gold particles (nuggets) in a sample. If a nugget is selected during a traditional sampling process, researchers can overestimate the amount of gold in the sample. But if the nugget is missed, the gold can be underestimated. For gold exploration and mining, this variability can lead to inaccurate results and costly mistakes.

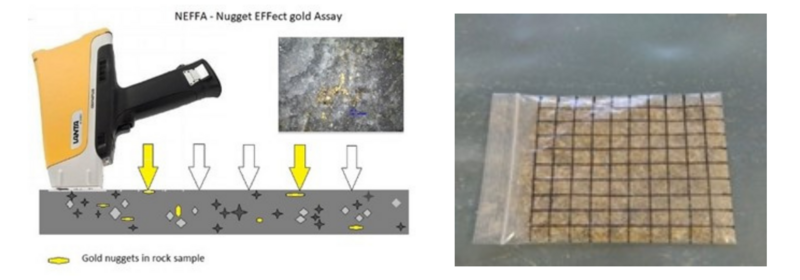

The Nugget Effect Gold Assay (NEFFA) technique aims to turn the traditional challenge associated with the nugget effect into an opportunity. NEFFA attempts to measure the nugget effect through multiple nondestructive, systematic analyses of a geological material (typically crushed rock or crushed drill core) to identify the presence of gold or other precious metals based upon its distribution within the sample.

NEFFA completely redefines and reduces the traditional sample preparation procedure and aims to provide semi-quantitative gold results using portable XRF analyzers to identify samples of potential interest for further laboratory analysis.

Here’s how it works:

- Representative samples of 20–30 g, depending on the nature of material, are isolated in a medium such as a clear sample bag or under plastic film to ensure that there’s no contamination from an external agent

- The sample is distributed evenly over a 10 cm × 10 cm square with the depth of the material being no thicker than 2 mm

- A grid or matrix is placed over the sample, with individual matrices measuring 1 cm × 1 cm

- Measurements are performed within each square cm, and the average of all results is reported

- The technique is most effective on crushed rock or crushed drill core samples with a grain size 3 mm, but not on homogenized pulp samples

- Rotary air blast and reverse circulation (RC) samples can be analyzed directly

This method takes the throughput advantages of GERDA for general exploration projects and adds additional value for gold exploration by providing gold estimates using XRF.

We acknowledge this method may be considered non-traditional. Portable XRF’s weaknesses in analyzing gold are well known (elemental spectral overlaps can cause false positives, relatively high LODs compared to the lab, and fire assay is the best technique to use), however the inventors’ initial work using GERDA and NEFFA suggests meaningful gold data and cost savings are possible with this system. Also, local radiation safety and licensing requirements must be followed with any proposed implementation of this technique.

By Todd Houlahan - Director, International Mining Group

Todd graduated from the University of Newcastle, Australia in 1993 with a degree in soils and hydrology. For the past 18 years, Todd has been a leader in the portable XRF revolution in the mineral exploration and mining industries, publishing numerous papers on the subject and presenting at international conferences. For the past 10 years, Todd has led Olympus’ International Mining Group helping explorers, miners, and their shareholders achieve cost efficiencies by using the best portable XRF and XRD technology solutions.

To know more about Automated, Robotic Innovations for Analyzing Geological Samples with Portable XRF, visit https://trisco.com.ph/ or email at trisco@pldtdsl.net