By: Engr. Jeffrey Geronimo

Data remains one of the most important assets of any mining company – and for these to become assets, these must be accurate and reliable. Data drives mineral exploration and mining operations. However, with the sheer volume of data we obtain, no one would object that these are usually overwhelming to manage; from the location and geochemistry of every hand sample; to the structural-geochemical-geophysical information collected from the nth drill hole just to define the resource; and even up to the 4D mine model showing the depth, thickness, grade.

Gathering geoscience data is crucial for a mining project. Millions of pesos are invested in the process of obtaining new and managing old data. New data brings fresh interpretations to keep mine models updated. Older data may increase in value as the degree of confidence becomes higher proven by the new data obtained. In addition, discoveries and deeper understanding of the project are often attained by continuously reinterpreting data from the past.

When effectively managed, geoscience datasets can be aggregated to generate subsurface and resource models that underpin critical financial and engineering decisions.

THE BIGGEST CHALLENGES: DISCOVERY, ACCESSIBILITY, AND SHARING

What data do we have? Where are these? How do we access these? These are three of the biggest data management challenges faced by mining companies. In most instances, files are just locally stored on each of the user’s laptops or desktops with the occasional habit of backing it up via the company’s file server. Moreover, sharing of valuable company data is done by just using e-mails, flash drives, FTP servers or even just through social media platforms. All these methods provide limited traceability and will compromise data security.

While the abovementioned file management styles can get the job done, these could eventually reduce business efficiency and lead to reduced productivity. Do we have the latest version of the drillhole data? What if I was basing my work on outdated data the whole time? Where was the document saved by my colleague prior to his leave of absence? It is a formula for disaster! Therefore, having a transparent process workflow can ensure geoscience data management be aligned and supported in mining projects.

THE SOLUTION: STRATEGIC GEOLOGY MODELING

Paramina Earth Technologies, Inc. is proud to bring the golden standard for geoscience data management. Through our “Strategic Geology Modeling” solution developed by Dassault Systèmes, it blends the power of the industry-leading 3DEXPERIENCE platform to ensure customers unlock and harness the value held within their geoscience data. It seamlessly integrates GEOVIA Surpac, the world’s most popular geology and mine planning software, and ENOVIA Project & Document Management applications.

Strategic Geology Modeling enables multiple users to work safely and securely on the same data and also at the same time. It enables tracking and managing user access and file permissions on top of retaining and tracing all changes to the data via document versioning. This gives the manager confidence that the latest interpretation, model, or plan uses the most up-to-date information - allowing real-time decisions and improved business agility.

With Strategic Geology Modeling, your geoscience datasets are safe as these are securely stored in the 3DEXPERIENCE platform - whether on a public or private cloud, or on-premise. With an intuitive and user-friendly interface, users can simply drag-and-drop data on the platform into the GEOVIA Surpac graphics window to begin work - no need to undergo tedious conversions! It also enables:

- Document versioning for traceability and accountability

- Check-in/out of data

- The ability to ‘sync’ data for fast visualization

- User file and folder permissions

- Bookmark workspaces and folders to create personalized views

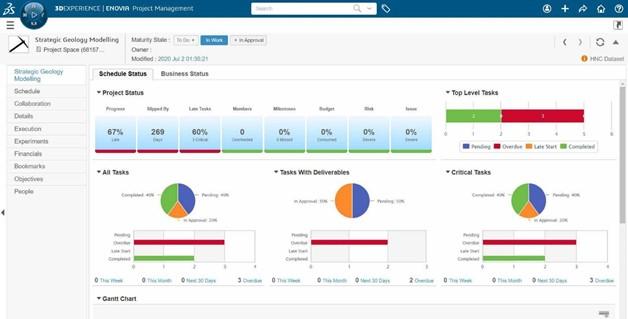

The synced geoscience data on the platform is accessible anywhere and from any device. Users can build customized dashboards containing the applications and data of their choice, providing a dynamic real- time view of operational information and KPI’s - accessible via web browser.

Strategic Geology Modeling combines these benefits with GEOVIA Surpac’s out-of-the-box functionality such as drillhole database, surfaces, and solids modeling tools. This allows geologists to truly represent the real world with a digital twin of the subsurface environment.

The evolution of the geology model from interpretation, model generation to validation, can be tracked using ENOVIA’s Project Management applications. Managers can assign tasks, create a project plan, and monitor the progress against the plan using various charts. This complete project visibility in real-time means issues or delays are addressed as soon as they occur, reducing the impact on the business and allowing decision-makers to make critical business decisions faster. This undeniably improves business performance and operational agility.

Once the model is uploaded to the 3DEXPERIENCE platform, content can be shared with all stakeholders via collaboration tools such as Communities & Conversations, Dashboards and Collaborative Tasks. Users can dynamically visualize GEOVIA Surpac content in 3D within the platform. They can also engage with colleagues or contractors at the same time through 3DSwym communities and conversations, or comment on the data itself.

The connection enabled by our Strategic Geology Modeling solution saves time and helps the user identify issues and bottlenecks earlier in the modeling process. These dynamic datasets and user-centric collaboration help staff understand the real-world problems that impact business performance and agility, ensuring operational excellence in the age of mine digitalization. Let Paramina Earth Technologies, Inc. be your partner towards your mining journey! Contact paramina_solutions@paramina.com or www.paramina.com for more information.

REFERENCE: Dassault Systèmes. (2021). Geoscience Data Management: Challenges and a Solution.