Philippine Mine Safety and Environment Association presented the virtual edition of 67th Annual National Mine Safety and Environment Conference (ANMSEC) last November 24-26, 2021 with the theme "Pusong Minero: Celebrating 67 years of responsible mining with the quiet heroes of the pandemic." The event was also made possible in cooperation with the DENR-MGB.

One of the highlights of this annual event is the awarding of the best mining companies. The winners of the 2021 Presidential Mineral Industry Environmental Award are the following:

~ Mineral Processing Category: Mindanao Mineral Processing & Refining Corporation

~ Quarry Operation Category: Republic Cement and Building Materials, Inc. – Bulacan

~ Surface Mining Operation Category: Berong Nickel Corporation

PMSEA and DENR- MGB also recognize the Mine Safety - Best Practices and key speakers from the industry who have stories and milestones to share during the occasion.

One of the guest speakers was Engr. Marcial H. Mateo (Chief, Mine Safety, Environment and Social Development Division, Mines and Geosciences Bureau). His presentation’s title is “Mine Safety and Health Management”.

Laws on Mine Safety and Health

Engr. Mateo’s topic is relevant not only to people within the industry but also to those who believe in anti-mining sentiments. Why? It is possible that some people dislike mining because they are unfamiliar with the complexities of owning and managing a mine site.

Mining is not just getting minerals from the ground. There are laws in our country that regulate and mandates a lot of requirements from mining companies. We have laws about the protection of our environment, and laws that protect the rights and safety of workers as well. Engr. Mateo’s presentation starts with an enumeration of Philippines laws that cover mining companies, particularly Laws on Mine Safety and Health.

From Mines and Geosciences Bureau, they have:

~ RA 7942 - PH Mining Act

~ DAO No. 2010-21 - IRR of RA 7942

~ DAO No. 2000-98 - Mine Safety and Health Standards, 2000

~ DAO No. 1997-30 - Small-scale Mine Safety Rules and Regulations

~ MC No. 2021-006 - Safety and Health, Environment and Social Development and Management (SHES) Manual

~ MC No. 2018-02 - Guidelines for Compliance Monitoring and Rating Scorecard of Mining Permits/Contracts

Mining companies also comply with laws from Department of Labor and Employment (DOLE), namely:

~ PD 442 - Labor Code of the Philippines

~ RA 11058 - An Act Strengthening the Compliance with Occupational Safety and Health Standards

~ RA 10757 - An Act reducing the retirement age of mine workers from 60 to 50

~ OSH Standards as Amended, 1989 (Yellow Book)

From Department of the Interior and Local Government (DILG), mining companies follow the:

~ PD 1185 - Fire code of the Philippines

~ RA 9561 - Laws on illegal possession, manufacture, dealing in, acquisition or disposition of explosives

Lastly, Department of Health’s laws on health and safety addresses particular health concerns and diseases. Mining companies comply with these laws and guidelines as well.

~ PD No. 856 - Sanitation Code of the Philippines

~ RA 9165 - Drug free workplace

~ RA 11036 - Mental Health Service in the Workplace

~ EO 187-03 - Tuberculosis

~ DOLE DA 05-2010 - Hepatitis B

~ RA 8504 - AIDS and HIV

Safety and Health Workplan

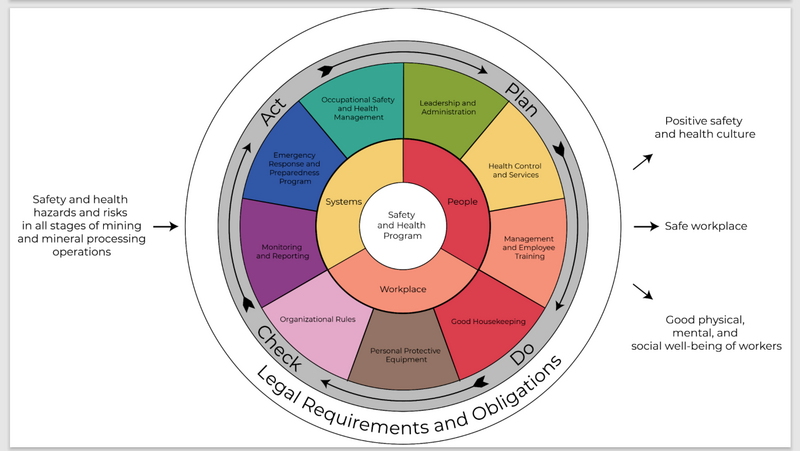

A workplan in important in a mine site as this provides guidelines on how to properly implement the laws and requirements that covers the various aspects of health and safety.

Mine Safety and Health Standards

This states that “All Contractors, Permittees, Lessees, Permit Holders and Service Contractors shall strictly comply with all the rules and regulations embodied under Department Administrative Order No. 2000-98, otherwise known as the ‘Mine Safety and Health Standards.’"

Annual Safety and Health Program

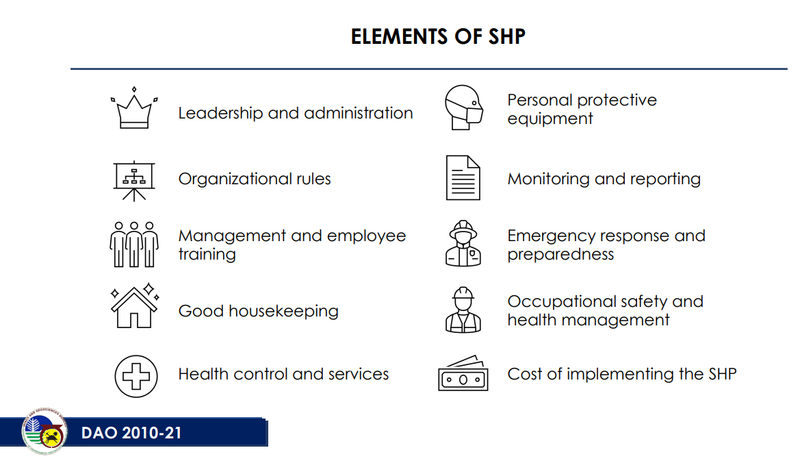

The Regional Director shall require a Contractor, Permittee, Lessee, or Permit Holder to submit a Safety and Health Program covering its area of operations within fifteen (15) working days before the start of every calendar year with the following terms and conditions listed in Elements of SHP chart.

DAO 2000-98 - Mine Safety and Health Standards

In order to assure mine safety and health standards, there are certain steps and requirements to follow. DAO 2000-98 provides some specifications on the matter. The first step is the establishment of a safety and health organization, and then having trained safety officers within the organization.

“Employer shall establish and provide for a safety and health office which is independent from other offices under the direct and immediate control and supervision of the Manager who shall be primarily responsible for the formulation and effective implementation of the company's safety and health program and enforcement of these rules and regulations.”

What are the basic qualifications of a Safety Officer? All Safety Engineers and Safety Inspectors of mining/quarrying operations shall be duly registered with the Regional Office and the corresponding permit shall be issued for this purpose (MGB Form Nos. 15-1, 15-2 and 15-3). For permanent registration of Safety Engineers, one is required to be a current licensed Mining Engineer with at least one (1) year supervisory experience in mining /quarrying operations and/or mine safety work; or currently licensed Engineer, Geologist or Chemist with at least five (5) years experience in mining/quarrying operations and/or mine safety work. The applicant for the position must undergo 40 hours of OSH training/seminars.

Permanent Registration for Safety Inspectors should be a graduate in any Engineering, Geology or Chemistry course with at least one (1) year experience in safety work or two (2) years of experience in mining operations; or a college undergraduate in any Engineering, Geology or Chemistry course with at least two (2) years of experience in safety work or three (3) years of experience in mining operations; or at least high school graduate with four (4) years of experience in safety work or five (5) years of experience in mining operations.

A Permanent Safety Engineer/Inspector permits shall be subject to renewal every three (3) years with the Regional Office. A Temporary Safety Engineer/Inspector Permit shall have a term of one (1) year from the date of issuance thereof, renewable every year.

Employees with at least ten (10) years of experience either in safety work or mining operation may be deputized by the employer as safety men, with the designation of a deputy safety inspector which shall be reported to the Regional Office.

Health Hazard Control

There are a lot of health hazards in a mine site. The guideline states, “An employer may not establish an emergency hospital and/or dental clinic in his workplace as required where there is a hospital or dental clinic located not more than five (5) kms. away from the workplace, or which can be reached in twenty-five (25) minutes of travel. Appropriate standby emergency transport vehicle shall be provided by the employer for the immediate transfer of the sick/injured worker to the hospital.”

Other safety measures that are required include having a Central Safety and Health Committee (CSHC) which is supposed to be established within one month from the start of the operation. The CSHC shall provide a forum for consultation and cooperation between the employer or manager of the mine, employees and members in initiating, developing and implementing measures designed to ensure the safety and health of employees at the mine. It shall also conduct a monthly safety meeting and the minutes of which to be submitted to the manager/employer and the Bureau/Regional Office.

Safety and Health Training is also required to be provided by the employer to the employees. Employees with no surface/underground mining experience shall experience shall receive no less than twenty-four (24) hours of training. And the, all employees shall receive no less than eight (8) hours of refresher training no less than once each twelve (12) months.

Another requirement is the Emergency Response and Preparedness Program. The employer shall ensure the preparation of an emergency response preparedness program prior to commencement of any mining operation which covers the identification of hazards that might cause emergency at the mine, assessment of every perceivable risk that may lead to a medical emergency, and to have controlling measures that will prevent or deal with the emergency. An emergency drill should be conducted quarterly for effectiveness of the program. Employers is required to submit to MGB a copy furnished to the Regional Office, a report on the conduct of the emergency drill.

-----

Reference:

https://pmsea.ph/67th-anmsec/