There are many ways and technological advancements that are used in mine sites that prevent disasters and address issues like ground stability at end of mine. One of the most fascinating techniques used by OceanaGold Corp. in assuring the safety of employees and protecting the environment is the use of the Paste Backfill System.

This topic and more were discussed by Engr. Jason N. Magdaong during the second day of PMSEA’s virtual event, Annual National Mine Safety and Environment Conference last November 24-26, 2021.

On the second day of the conference, the PSEM Minerals Industry Symposium had OceanaGold Philippines Inc. (OGPI) as one of their presenters. Engr. Magdaong is the Environmental and Occupational Health, Safety Manager of OGPI. His presentation, "Working Safe Underground: Managing Safety Hazards with Management System, Protocols, and Use of Technological Solutions in Didipio Underground Mine" was a through discussion on all the safety measures and standards applied in the Didipio mine of OGPI.

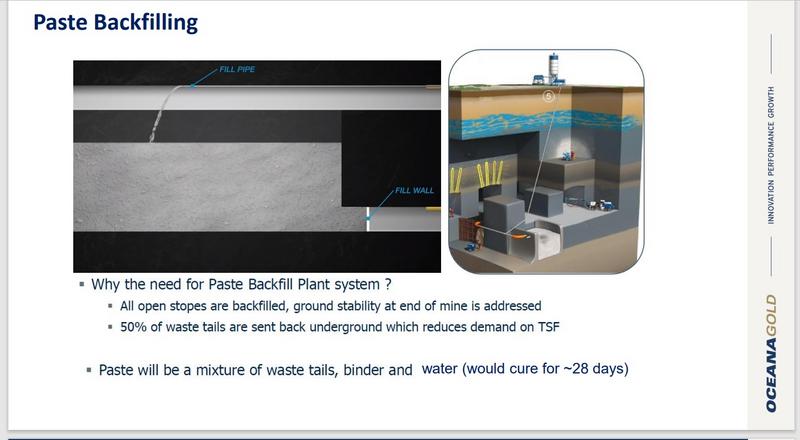

OGPI has various strategies and measures on how to assure safety in the underground mine such as having an efficient Ventilation System and the use of ventilation measuring equipment, carefully planned Ground Support Installation, Refuge Chambers, Escape Ladderway, and more. And then there is the Paste Backfill System which is not a new technology. However, the Paste Backfill System in the Didipio mine is the first and the only one in the Philippines.

Paste backfill is an engineered mixture of fine solid particles (with binder) and water. The paste mixture can be placed in stopes (an excavation in a mine or quarry in the form of a step or notch), and binders may be added (or not) depending on the kind of strength needed for the backfill. Paste backfills are also important in tailings management and mine backfill alternative. Binders are used in paste backfill where structural strength is required of the backfill and where resistance to liquefaction is necessary.[1]

In a short interview with Engr. Magdaong during the virtual Q&A session, we asked him how can the Paste Backfill System help decrease the environmental impact of Didipio mining activities? And how can this technology provide a safe working environment for OGPI employees?

“Paste Backfill System decreases environmental impact by reducing the volume of tailings disposed in the tailings storage facility (TSF) and corresponding reduces the required size of the tailings storage and reducing the required clearing and footprint of the TSF,” Engr. Magdaong said.

“Associated risk of having bigger TSF is also reduced. Having a paste backfilled stopes in the underground, it provides a more stable and safer working area in any axis of mine production, may it be on the sides, above or below.”

Engr. Jason N. Magdaong during the PSEM Minerals Industry Symposium last

Nov. 2021. He is the Environmental and Occupational Health, Safety Manager

of OceanaGold Philippines Inc. (OGPI). [Screenshot by PRJ]

Lay people who are unfamiliar with the technology behind Paste Backfill System might feel some apprehension or doubt that a mining operation can be safely done without destroying the environment. Perhaps it is because mainstream media hardly mention that such a technology even exist in mining. Or maybe this technique in tailings management and ground stabilization and all other safety features in a mine are unheard of to most people. This presents a new challenge for mining companies in effectively communicating topics related with science and technology, OceanaGold Philippines Inc. is one of the notable mining companies who make an effort to help the general public understand how responsible mining is indeed possible.

------

Reference:

[1] https://sites.google.com/site/mininginfosite/miner-s-toolbox/backfill/paste-backfill

additional info from - https://pmsea.ph/67th-anmsec/

-----

Acknowledgement: Thank you, Engr. Jason Magdaong.

-----