The early design stages are the best time to fully explore ground risks and focus teams on mitigation and intervention, before a project gets too far down the track. Doing this formally and methodically through the Potential Failure Mode Analysis (PFMA) framework offers best-case potential for project success.

How PFMA works in Geotechnical Engineering

Potential Failure Mode Analyses (PFMA) offer a rigorous, transparent and defensible process to get quickly to the core of complex geotechnical problems, track mitigations and effectivity outcomes.

Geotechnical problems are routinely complex due to the range of unseen unknowns in the ground. The problem and potential consequences can be multiple and confusing and very difficult to resolve through informal process.

The most common result following that path is loss; either through time or cost due to poorly conceived investigation, improper or poorly conceived design, and contract over-runs due to unforeseen conditions. In the worst case, failure of critical infrastructure or components can lead to project closure.

For Project Managers, it is critically important to not get lost in the confusion and to identify and resolve the crux issue as quickly as possible. The PFMA is the way to save time and money in the most efficient and transparent manner possible.

RDCL’s Application / Using PFMA with RDCL

RDCL is skilled in the use of Failure Mode Analyses. In particular, for the assessment of dam structures where the consequence of failure can be very high, and for all significant ground investigation for infrastructure where unforeseen ground presents the greatest risk in terms of cost and time.

Projects (https://www.rdcl.co.nz/projects/) where we have applied PFMA include our work on the Harapaki Windfarm for foundation assessment including use of appropriate investigation techniques, regional flood stopbank (levee) upgrades and emergency works and design and construction of the Kereuru Water Storage structure, all in New Zealand.

In the Philippines we have assessed geotechnical implications for the Wawa Water Storage project investigations and for tailings dams on leading mine sites.

Identify Sources of Failure Before they Happen

Developed in the 1940’s, Failure Mode Analyses seeks to document the potential sources of failure, what the consequence of the failure may be and how to mitigate the consequence or remove the potential source of failure.

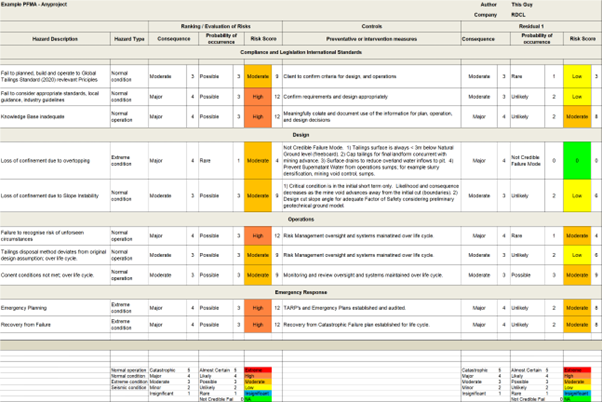

The method is used by leading design and design critical companies throughout the world as a powerful method to capture and communicate risk. An example of a part snapshot of a hypothetical Tailings storage facility is shown.

Failure mode analyses can therefore benefit all stakeholders in a significant (or even simple) project by developing a better understanding of design, construction or operational weaknesses.

This ties into our philosophy and drive at RDCL to help promote better decision-making and costing through proper and appropriate ground investigation as we discussed in our previous article (Philippine Resources Journal, March 2024).

Our approach of considering the geotechnical aspects of the project or piece of infrastructure over the whole life-cycle is explained here in our video: https://www.youtube.com/watch?v=1Mtoz0B-LYk&ab

Standard Risk Assessment

Standard Risk Assessment methodologies such as is ISO 31000, the international standard that sets out the principles and guidelines for effective risk management, guide the development of the PFMA.

This standardised approach ensures a commonality of language and consistency of approach allowing organisations to communicate their risk and risk mitigation strategies effectively and move quickly on resolution.

Guidelines for the use of Failure Mode Analyses are freely available from the World Bank (2021) and other leading jurisdictions and organisations.

How to make it work / Where the rubber hits the road

In all cases, the PFMA process includes collaborative, workshop based efforts by stakeholders, led by skilled practitioners in risk assessment backed by expert advisors. To move quickly and accurately, it is important to bring everyone along for the ride from early in the process, keep the document alive and regularly return to check on assumptions and the effectivity of mitigations and solutions applied.

Without closing the loop on the action-checking process, much of the group’s efforts are wasted. By engaging an external party to help guide the process, you achieve an impartial, best for project approach and are supported in keeping critical actions on track.

Partner with us and take action at the time when it is most impactful to your project.

Cam Wylie, Director, RDCL

Cam Wylie is the Managing Director, CEO & Principal Engineer at RDCL Limited. With 30 years in the industry, Cam is a Chartered Professional Engineer with extensive overseas experience, working on major projects in the Philippines, Indonesia, Africa, Australia, and New Zealand. His expertise includes Project Management, Geotechnical/Dam Engineering, Mining, Roading, Infrastructure, large subdivisions, and Residential Dwellings, and he is a contributor to the Hawke’s Bay Cyclone Gabrielle Engineering Leadership Group.