By Thomas Hanna, PG, Technical Director – Johnson Screens

The use of Shur-Pak glass beads is becoming a better choice for the long-term operational costs of wells.

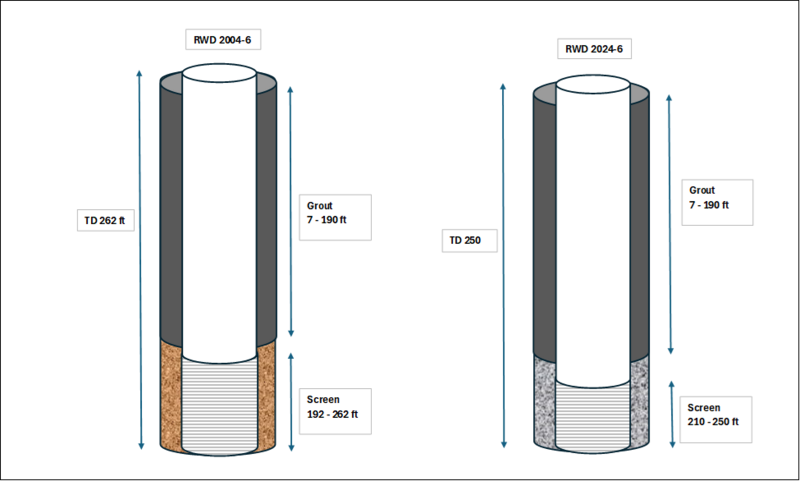

This article compares the performance of two nearby wells—RWD 2004-6 and RWD 2024-6—constructed in the Quaternary High Plains aquifer near Lancaster, Nebraska, USA.

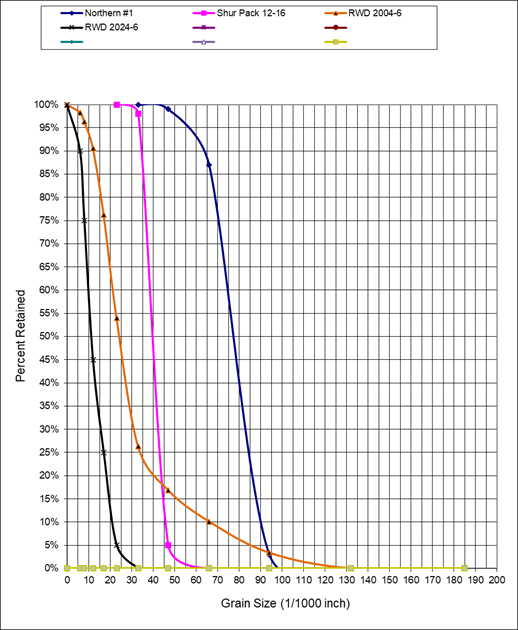

These municipal supply wells were drilled approximately 600 feet apart and constructed using similar methods, materials, and dimensions, with one key difference: RWD 2004-6 was completed in 2004 using #1 Northern gravel as a filter pack, while RWD 2024-6, drilled in 2024, used Shur-Pak 12-16 glass beads.

Glass beads are increasingly favored in well construction due to their uniform size, smooth surface, and chemical inertness.

Compared to natural gravel, which varies in shape and composition, glass beads offer consistent porosity, enhanced hydraulic conductivity, and reduced biofouling risk, resulting in lower well ownership costs.

Well Design and Construction

The general geology of the site, based on geologic well logs, shows the upper 80–150 ft of the aquifer consisted of silt and clay consistent with loess and glacial deposits. Below this, fine to coarse sands of the aquifer were deposited over shale.

Sand thickness ranged from approximately 80–266 ft below ground surface (bgs) in RWD 2004-6 and from 149–248 ft bgs in RWD 2024-6. Static water levels ranged from 70–80 ft bgs.

The wells were drilled using reverse circulation mud rotary. Bentonite- and polymer-based drilling fluids were used, and viscosities were thinned with Nu-Well 220 clay dispersant before development.

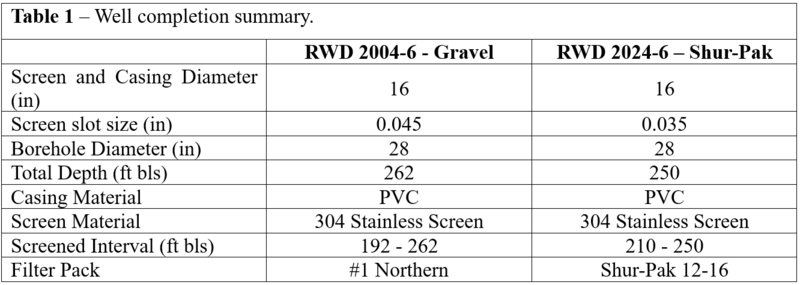

Both wells were completed with 16-inch 304SS wire-wrapped screens and PVC risers:

-

RWD 2004-6 (Gravel): 70 ft of screen, 0.045-in slot, #1 Northern gravel

-

RWD 2024-6 (Glass): 40 ft of screen, 0.035-in slot, Shur-Pak 12-16

Filter packs were installed by the tremie method, and the annular space was grouted from approximately 190 ft bgs to 17 ft bgs with 3/8-inch bentonite chips. The upper 10 ft were sealed with neat cement to complete the sanitary seal (Table 1).

Well Development

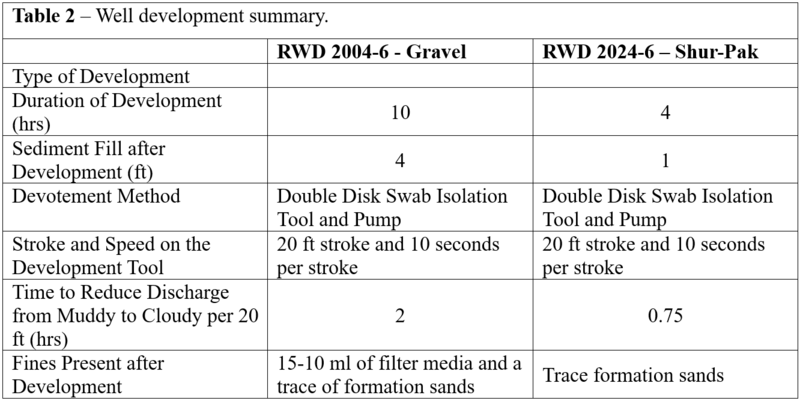

Both wells were developed using a double surge block tool, operated at a 20-ft stroke and 10-second interval, while pumping at approximately 400 gpm.

The results presented in Table 2 show that RWD 2004-6 (Gravel) took approximately 2 hours per 20-ft interval to reduce water from muddy to cloudy, and an additional 30 minutes to clear completely.

Fines present at the end of each interval were about 10–15 mg/L. RWD 2024-6 (Shur-Pak) took 45 minutes to go from muddy to cloudy per interval, and 10 more minutes to clear. No fines were observed post-development.

Test Pumping

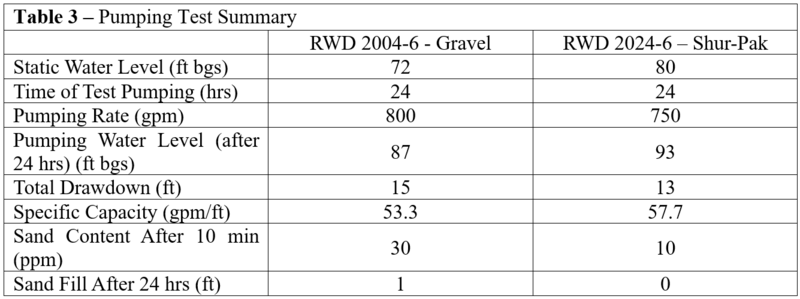

Both wells underwent a 24-hour pumping test.

RWD 2004-6 (Gravel) was pumped at 800 gpm with 15 ft of drawdown, resulting in a specific capacity of 53.3 gpm/ft. The sand content during pumping was 30 ppm, and the fill noted at the bottom of the well was 1 ft.

RWD 2024-6 (Shur-Pak) was pumped at 750 gpm with 13 ft of drawdown, resulting in a specific capacity of 57.7 gpm/ft. The sand content at the end of pumping was 10 ppm, and no fill was noted at the bottom of the well. The pumping test summary is presented in Table 3.

Conclusion

The well completed with glass beads (RWD 2024-6) demonstrated significantly faster development, requiring less than half the time needed for the gravel-packed well. Additionally, it produced cleaner water with no fines or sediment accumulation following development or pumping.

Despite having a shorter screened interval and a finer screen slot, it achieved a slightly higher specific capacity, indicating improved hydraulic efficiency and supporting the performance advantages of glass bead filter packs in well design and construction.

Shur-Pak glass beads are a good solution for constructing higher-capacity wells that are more economical to own compared to wells completed with gravel filter packs.

For further questions, contact Thom Hanna at: thom.hanna@johnsonscreens.com.