In today’s mining landscape, success is no longer measured by output alone. Clients worldwide are being asked to demonstrate environmental responsibility, meet increasingly stringent regulatory frameworks, and secure their social license to operate while improving operational efficiency.

In regions with high rainfall or limited tailings storage areas, these challenges are even greater. For mining companies ready to answer that challenge, Metso offers a compelling and proven solution: dry stacked tailings.

A smarter, safer approach to tailings

Tailings management has long been one of the mining industry’s most persistent and visible challenges. Conventional slurry-based storage systems, reliant on high water volumes and large tailings dams, come with known environmental, operational and safety risks. Catastrophic failures in recent history have only accelerated the shift toward alternatives that reduce these risks.

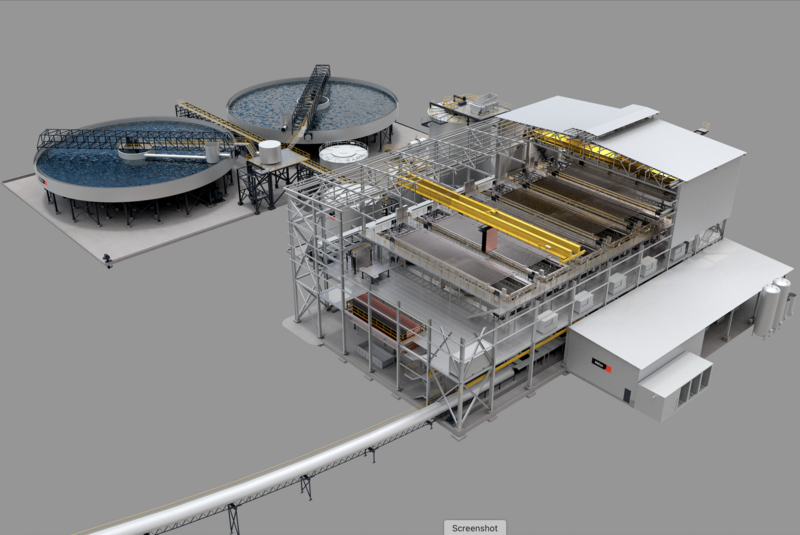

Metso’s dry stacked tailings technology is more than just a safer option; it’s a strategic investment into the long-term resilience of your operation. By removing water from tailings through high-efficiency filtration and stacking the material dry, the tailings dam is eliminated, water recovery is significantly increased, and the site’s environmental footprint is lowered.

Sustainability at the core of innovation

For Metso, sustainability isn’t an add-on—it’s engineered into every solution. Their dry stacked tailings systems use cutting-edge pressure filtration, such as the Larox® FFP (Fully Automated Filter Press) and the VPA (Vertical Plate Pressure Filter – Airblow) filter, to achieve up to 90% water recovery. These systems are modular, energy-efficient, and scalable to fit the needs of both greenfield and brownfield operations.

From Chile’s high-altitude Salares Norte gold mine to the Skouries project in Greece, Metso’s dry stacking solutions are already proving their value in demanding, water-scarce environments. Part of Metso’s Metso Plus portfolio of equipment, parts, and services designed to deliver enhanced performance and proven sustainability benefits, helping customers operate more efficiently, profitably, and responsibly.

End-to-end solutions for real-world impact

What sets Metso apart is not just its technology, but its deep commitment to helping clients through the entire tailings lifecycle. Metso offers:

-

Tailings test work and feasibility studies

-

Customized filtration and thickening solutions

-

Process water recovery and closed-loop systems

-

Digital simulation tools like Geminex™ for performance optimization

-

Life Cycle Services (LCS), including installation, training, spare part plate pack maintenance, and performance audits, based on needs.

This end-to-end approach ensures that tailings management is not just compliant but optimized, maximizing throughput, minimizing downtime, and creating new opportunities for value recovery from waste.

Turning Responsibility into Results

For future-focused mine operators, dry stacking is more than a compliance measure; it’s a way to build trust with regulators, investors, and surrounding communities. It’s a way to show the world that sustainable mining is not only possible, but also profitable.

With Metso as your partner, you don’t need to compromise between performance and responsibility—you get both. Let’s move tailings from liability to legacy.

Talk to Metso today about how dry stacked tailings can transform your operation for good. For local support, please contact Lawrence Lazaro or Raz Raullo, at orderdesk.asia@metso.com, or visit our office in Manila. Visit our tailings management solution here