Eriez’ force-cooled suspended magnets balance strength, efficiency, and adaptability.

By: Dave Heubel, Global Product Manager-Magnetic Separation, Eriez

Tramp metal is one of the most persistent—and costly—hazards in mining and bulk material handling. Even a single fragment of iron can damage crushers, conveyors, or downstream equipment, triggering downtime and safety risks. Preventing these incidents before they reach critical systems is essential. But, as plants expand in scale and throughput, keeping tramp metal in check becomes more complicated. Traditional suspended magnets are often large and heavy, demanding extensive support structures that raise capital expenses and exacerbate installation challenges.

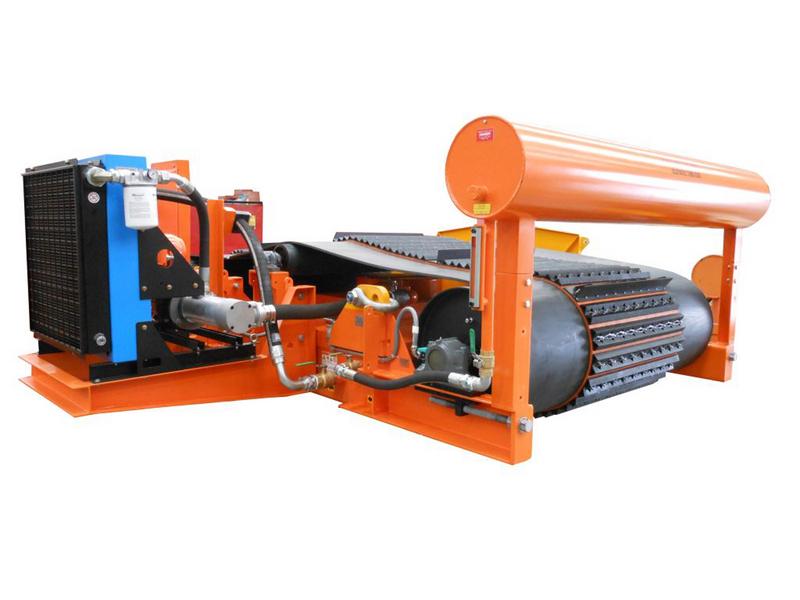

That’s where Eriez Compact Force-Cooled Suspended Electromagnets prove their value. By combining active cooling and a reduced footprint, they deliver the same powerful separation as bulkier units—without the same infrastructure needs. The payoff is clear: dependable tramp metal protection that matches the needs of modern, high-capacity plants.

Balancing Strength, Size, and Reliability

Developed by Eriez, a global authority in separation technologies, these magnets achieve exceptional performance through active cooling. Circulating oil through a heat exchanger dissipates heat more efficiently, enabling higher magnetic field strengths at lower operating temperatures. This innovation allows operators to install smaller, lighter units while maintaining the protection once possible only with traditional heavy designs.

Built for demanding environments, the magnets feature tightly wound VEOX anodised aluminum strip coils, rugged manganese bottom plates, and sealed oil expansion tanks for long service life. They are suited to applications ranging from coal and aggregates to limestone, cement, recycled materials, and municipal waste. Plants can choose self-cleaning models for uninterrupted operation or manual-cleaning units for simpler, more economical setups. Added monitoring tools, such as oil temperature sensors and conveyor speed switches, help ensure consistent performance and strengthen peace of mind.

Supporting Regional Industries

For resource-rich nations such as the Philippines, a compact design is more than a convenience; it’s a necessity. Many mining and aggregates sites operate in remote terrain where infrastructure is limited, and downtime carries a massive cost. Compact Force-Cooled Suspended Electromagnets address this reality by bringing together high-strength separation with easier installation, allowing operators to protect equipment without overbuilding structural supports.

A Longstanding Focus on Separation Technologies

This compact, force-cooled approach is just one example of Eriez’ decades of innovation in magnetic separation. Having pioneered oil-cooled suspended electromagnets, the company continues to refine designs that meet the evolving demands of global resource industries. Eriez’ vast equipment portfolio, including metal detectors, vibratory feeders, flotation systems, recycling technologies, and more, is engineered to promote safety, efficiency, and sustainability.

For operators in the Philippines and beyond, compact force-cooled suspended magnets illustrate how Eriez innovation delivers practical solutions: protecting critical equipment, upholding throughput, and controlling costs—all while fitting the tighter footprints of advanced processing plants. As the global resource sector strives to do more with less, compact solutions will define the future of tramp metal protection—and Eriez is driving that future forward.

%20-%20Copy.jpg)