Projects involving dams and other hydroelectric infrastructure, such as shafts and tunnels, have a high geotechnical risk and are often located in remote, mountainous terrain so that application of high resolution, portable geotechnical equipment offers highly effective solutions to help de-risk a ground engineering project.

Our experience is that the use of these tools always improves the accuracy in the interpretation of ground conditions and very often provides a much more accurate representation of ground conditions over conventional drilling. This is because the tools measure the drillhole wall which is undisturbed relative to the core which might be highly disturbed due to drilling mechanics. The advantages are more accurate design, better understanding of ground and often a better project price.

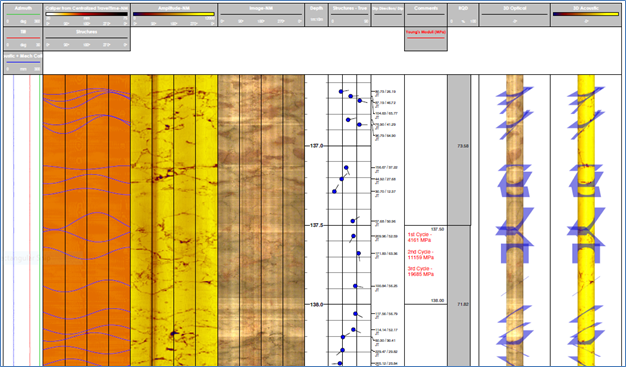

RDCL’s wireline geophysics equipment is highly portable and well suited for these projects, which include the identification of suitable hydroelectric sites, and fracture detection, prior to tunnelling (vertically and horizontally). Our acoustic and optical televiewers create very detailed imagery of rock structures which combined with our high capacity pressuremeter for in-situ measurement of rockmass modulus, greatly assists design and the evaluation of ground risks.

Why and What are Borehole Televiewers?

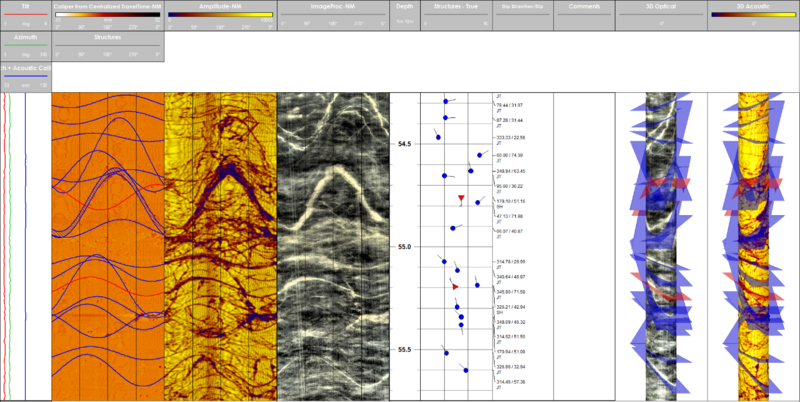

Televiewers provide a continuous, orientated, high-resolution image of the borehole wall, often superior to conventional core logs, which offers many advantages to geologists and geotechnical engineers,. The data provides repeatable, checkable information about geology, structure, fractures, stress orientation, provides depth control where core recovery is poor and importantly allows orientation of structures even where ground conditions are poor.

How Borehole Televiewers Work

The acoustic televiewer logs the borehole wall in terms of hardness, measuring the amplitude of a high frequency sound wave. Hard rocks reflect high-amplitude signals and soft rocks and fractures reflect low amplitudes. The individual measurements of reflected amplitudes are made continuously by a rotating a 360° transducer. The result is a map of the borehole wall with an individual resolution of about 2mm in ideal conditions. Acoustic Televiewer (ATV) data is aligned with magnetic north. Fractures and bedding planes appear as sinusoidal lines where the deepest point on the line is the direction of dip.

Tool centralisation is important to ensure similar travel time and signal strength in all directions. Data resolution reduces with wider diameter boreholes, and in some cases thick drilling mud due to signal dispersion. Because the acoustic televiewer is sensitive to rock hardness and can measure fracture orientations and apertures (lost in drill core), it has become an important geotechnical tool in both sedimentary and hard-rock formations. Acoustic televiewers most often in fluid filled holes to ensure the sound wave can travel through medium.

If data is required from dry boreholes (above the water line), the Optical Televiewer (OTV) should be employed. It measures the colour and shade of reflected light, basically a 360°camera. The borehole wall is lit by a ring of diodes on the tool and reflections are directed to a light-sensitive sensor via a conical mirror. Resolution is very high, with pixel sizes down to well below 1mm at HQ borehole diameter.

The optical televiewer provides an orientated photograph of the borehole wall at high resolution and without perspective. The system does not offer a travel time image, and log quality is dependent on clean borehole fluid if it is run below the water table. In slim holes, optical televiewer images can be of such high quality and value that it is usually worth flushing the borehole to remove mud from walls and replacing dirty fluid before logging.

Subsurface Data Output and Characterization using Televiewers

- Characterise ground conditions in terms of condition, stiffness, fractures and lithology

- Gain an understanding of the groundwater conditions

- Investigate the condition of existing structures associated with dams and tunnels

Borehole Televiewers + Pressuremeter Test

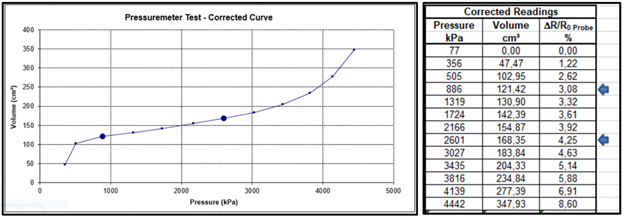

The Pressuremeter provides an indication of rockmass deformation modulus by inflating a bladder in a borehole to pressure the walls, with strain measured by strain gauges. The tool is suitable for soft rock and hard rock. These characteristics are for the design of important structures such as underground openings, and pile foundations for bridges and high-rise buildings. Pressuremeter tests provide parameters to assess stability, rock mass deformability (creep, rebound and permanent characteristics) that all feed into designs for tunnel linings, concrete dam foundations, bridge supports and lateral deflection analysis shafts.

Borehole televiewers and pressuremeters are cost effective portable systems that provide on-site geological and geotechnical data in real time outputs and processed outputs. RDCL’s downhole technologies provide effective rapid deployment for engineering design, works during construction and monitoring throughout the structure’s life.

Battle Proven Technology

The Philippines are one of the leading countries in the development of dams and tunnels in the Southeast Asian region. RDCL are based in Manila with staff and equipment. This means we can respond fast, mobilizing for domestic projects effectively and safely during a time when the world is restricted by global travel.

From Run-of-River hydroelectric systems, concrete dams, bulk water storage, pumped storage, mine tailings dams, subway tunnels and regular geotechnical applications, both the televiewer and pressuremeter has proved to be reliable and invaluable tools.