The new Atlas Copco’s XAS boX range is the result of 10 years of continuous development and addresses the changing needs of our customers. This range, from 400-850 cfm, combines the rugged durability you need with the performance efficiency you deserve. When we focus on efficiency within this range, it’s all about the strategic triangle of size, flow, and fuel efficiency. Excelling in one of these areas is wasted excellence if you cannot provide the other two. Therefore, our promise to our customers is an industry leading range of optimized size-to-flow compressors, which have unparalleled levels of fuel efficiency and autonomy.

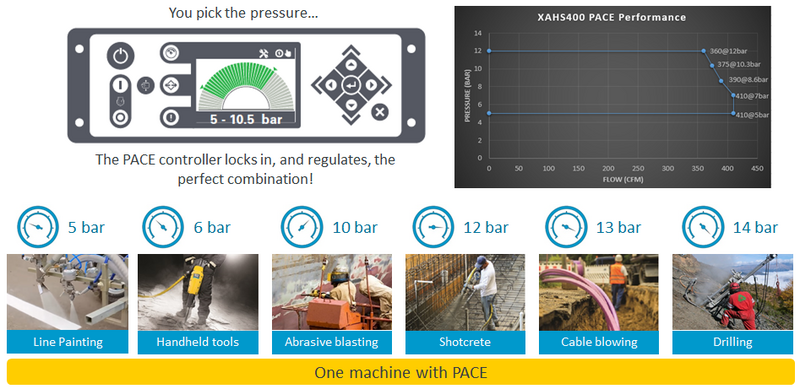

The XAS boX range comes with Pressure Adjusted through Cognitive Electronics (PACE) technology. This electronic pressure regulation system brings a wider pressure range to cover more applications. PACE optimizes your compressor’s efficiency, especially at partial load or idle status and is the smart technology that increases your utilization and improves your compressor’s fuel economy.

This range is also designed to withstand the toughest working conditions. With a standard operating temperature range of -10°C to +50°C and a strong undercarriage, the range’s robust nature guarantees reliable operation. The design, controller and modularity put you in control. You will see we have also focused heavily on ease of service to ensure uptime and utilization. This range is all about you!

Huge number of Atlas Copco machines used in Slope Protection projects

Rebtrade International Corporation started its formal operations in 1980 as a trading company for specialty construction chemicals, particularly waterproofing and non-shrink grouts. In 1984, Rebtrade entered a manufacturing licensing agreement with an established Swiss manufacturing conglomerate. The thrust is to provide quality products meeting international standards using majority of its components from locally available sources. This created a major advantage for the company in terms of pricing and delivery, as our competitors sold finished products imported from either USA or Europe.

At present, Rebtrade has more than 50 specialty construction products such as Waterproofing, Waterstops, Fireproofing, Flooring Compounds and Treatments, Adhesives, Non-shrink Grouts, Epoxies, Caulks and Sealants, Concrete Admixtures, Firestops, Carbon Fiber, etc. Rebtrade represents various principal companies from Europe and America and have also exported products to different parts of Asia. The company is constantly evolving as more innovative products are being developed and introduced to the market to cater to all clients in the construction industry. It is now one of the leading manufacturing and trading companies in the country to date.

“Rebtrade International Corporation is one of the pioneers for specialty construction materials, slope protection and road stabilization installation. We started out as a trading company way back in 1980 for specialty construction materials. As we continued to expand and diversify, we needed to find good and reliable suppliers to help in our growth, that’s when we partnered with Atlas Copco. This was more than 8 years ago and to this day, Atlas Copco continues to be our go-to supplier for compressed air supply, among other things”, said Mr. Manuel Syyap, President of Rebtrade International Corporation. “We are happy that we have grown together with Atlas Copco, a company who shares our ideals and our vision. We hope that this partnership will continue in the years to come.”, he added.

Discover the products and services offered by Rebtrade International Corporation via www.rebtrade.com or contact them at info@rebtrade.com and +632 584 6070 to 71.

To know more about Atlas Copco’s range of products and services, visit https://www.atlascopco.com/en-ph/construction-equipment or email powertechnique.SEA@atlascopco.com.