Celsius Resources Limited is pleased to announce an updated JORC compliant Mineral Resource estimate (“MRE”) for the Sagay Copper Project (“Sagay” or “Project”), held under its Philippine Subsidiary, Tambuli Mining Company, Inc (“TMCI”) and located at the Island of Negros in the Philippines.

The update to the MRE at Sagay is largely based on the results from the 2023 drilling program at a shallow copper position located ~500m to the west of the main body of mineralisation discovered to date, as announced on 17th October 2023. This shallow copper zone offers Celsius the opportunity to investigate a low cost start up opportunity via a feasibility study which has been submitted to the Philippine Government.

Celsius Resources Managing Director, Peter Hume said:

“The greater definition of the shallow supergene copper at Sagay has increased both the Resource category and our own confidence in the ability to look at a new shallow sustainable friendly development option. The previous Mineral Resource1. only placed this area in the Inferred Category, and with this new update to the Mineral Resource, this area is now largely in the Measured and Indicated category, which allowed us to complete and submit a feasibility study to the Philippine Government2.

1 Refer to ASX/AIM announcement dated 7 November 2021 “Maiden Mineral Resource estimate (MRE) for the Sagay Project”

2 Refer to ASX/AIM announcement dated 8 January 2024 “Celsius’ Sagay Project applies for DMPF”

The Company has taken a sustainable approach to the proposed development of the Sagay Mineral Resource, similar to its flagship MCB project. Eliminating the use of a conventional tailings dam and using the tailings for environmental rehabilitation, along with processing the ore through gravity separation, therefore eliminates the use of chemicals. We are in the process of finalising the Project’s environmental impact assessment which will clearly demonstrate the Company’s commitment to environmental protection and preservation through advanced mining technologies.”

CLA Chairman, Atty. Julito R. Sarmiento added:

“The development of the Sagay Project can assist with meeting the global demand for green metals in an effort to transition to clean energy sources and achieve the global goal of net zero emissions by 2050 to stave off climate change calamity. CLA constantly takes serious efforts to develop genuinely responsible projects by tightening up our environmental managements systems and stepping up our social and environmental performance.”

THE SAGAY COPPER-GOLD PROJECT

Location

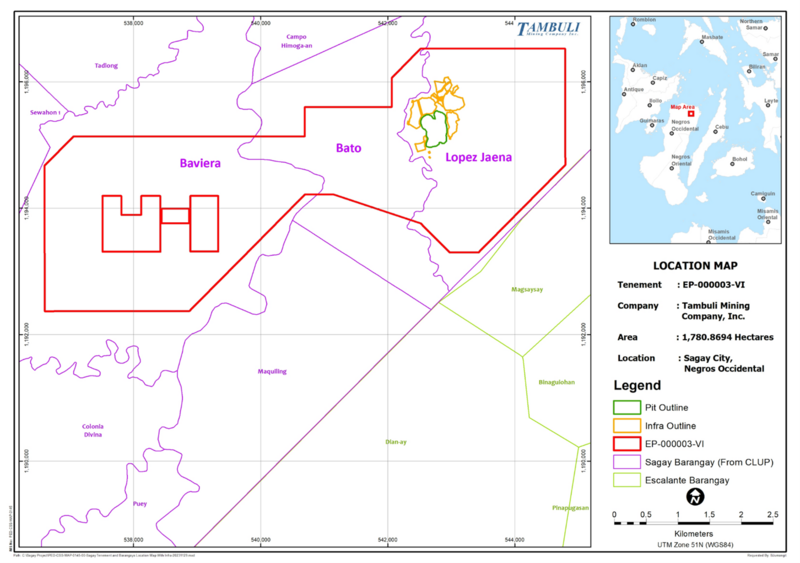

The Sagay Copper Project is in the north-eastern part of Negros Island, within the cities of Sagay and Escalante in the Province of Negros Occidental, Philippines (Figure 1). Negros Island is part of the central group of Islands in the Philippines commonly referred to as “the Visayas”.

The MRE for the Sagay Property is located at Purok Tan-ao, Barangay Lopez Jaena (see Figure 2).

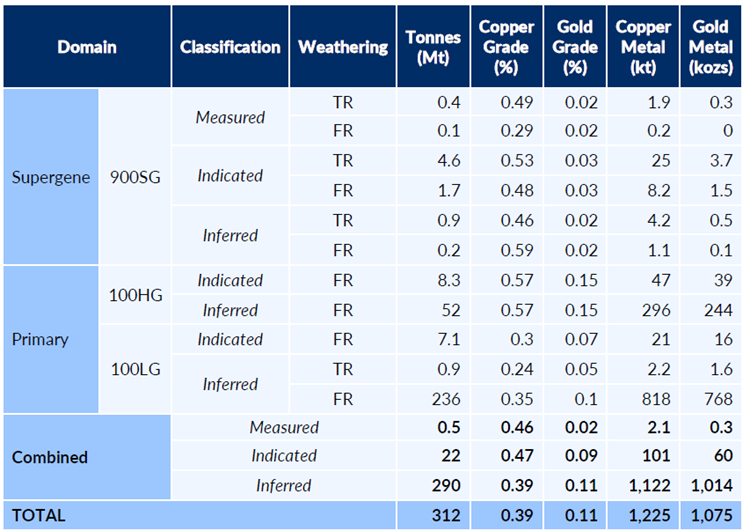

Mineral Resource Estimate

Drilling at Sagay has broadly defined a large-scale copper mineralisation which is interpreted to be a typical porphyry copper style of mineralisation, common throughout the Philippine archipelago.

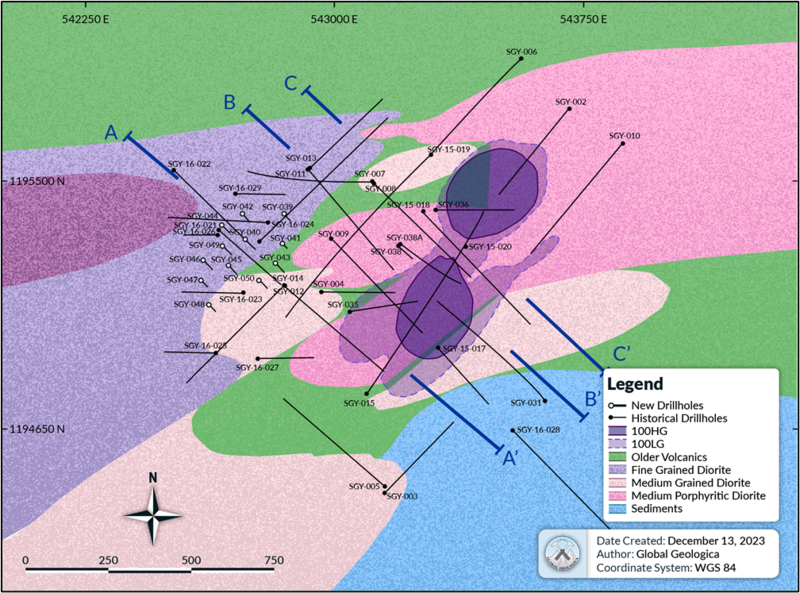

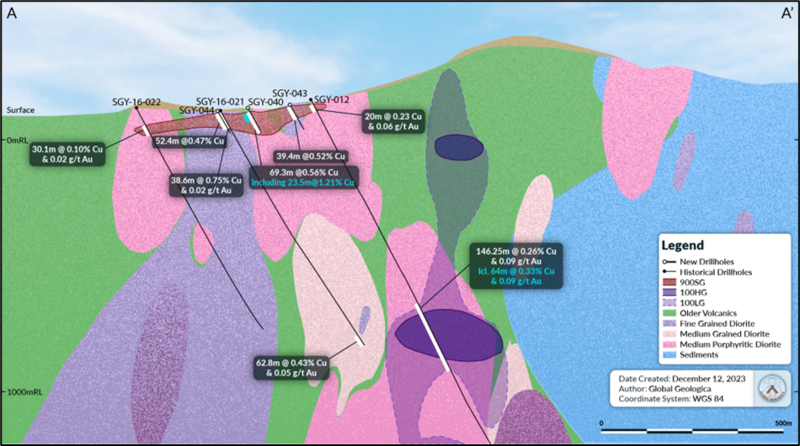

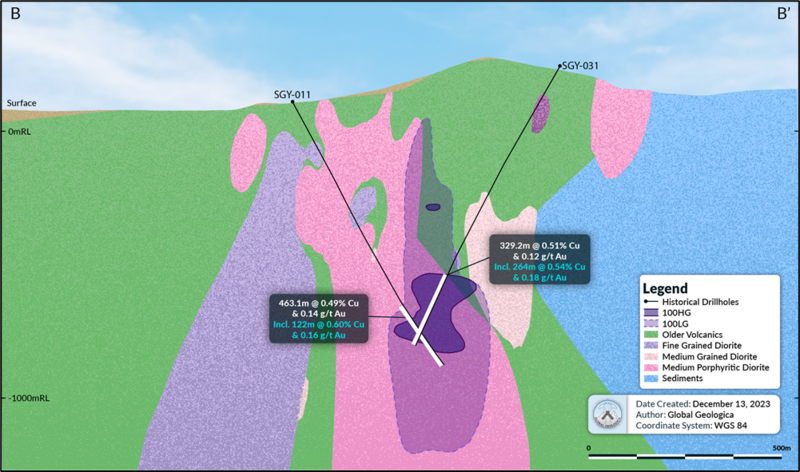

The copper mineralisation for the MRE at Sagay is defined by three defined mineralised domains, two of which (namely 100LG and 100HG) relate to a main body of copper mineralisation which exists underneath a local topographic high.

This topographic high relates to Purok Tan-ao with resistive siliceous rocks interpreted to be an eroded lithocap associated with the porphyry mineralisation.

A third mineralised domain (900SG) hosts a shallow flat lying supergene copper mineralisation towards the west of the main mineralisation underneath Purok Tan-ao and is possibly related to a satellite porphyry mineralisation. Figures 3 to 7 show a plan view and cross sections of the mineralised domains relative to the host rock geology.

The copper mineralisation at Purok Tan-ao is broadly constrained by a zone of mineralisation which exceeds 0.2% copper and is trending parallel to the main alteration and related intrusive host rocks.

A lower cut-off grade of 0.2% copper was applied in the reported MRE (summarised in Table 1) which aligns broadly with the expected economic limits of the likely mining and processing options considered at Purok Tan-ao.

Note for table of results: Calculations have been rounded to the nearest Mt of ore (to the nearest 100,000t where <10Mt), two significant figures for Cu and Au grade and to the nearest kt of Cu metal and kozs of Au metal (to the nearest 100t where <10kt). Some apparent errors may occur due to rounding. TR – Transition or partially oxidised Rock, FR – Fresh Rock.

Geology and Geological Interpretation

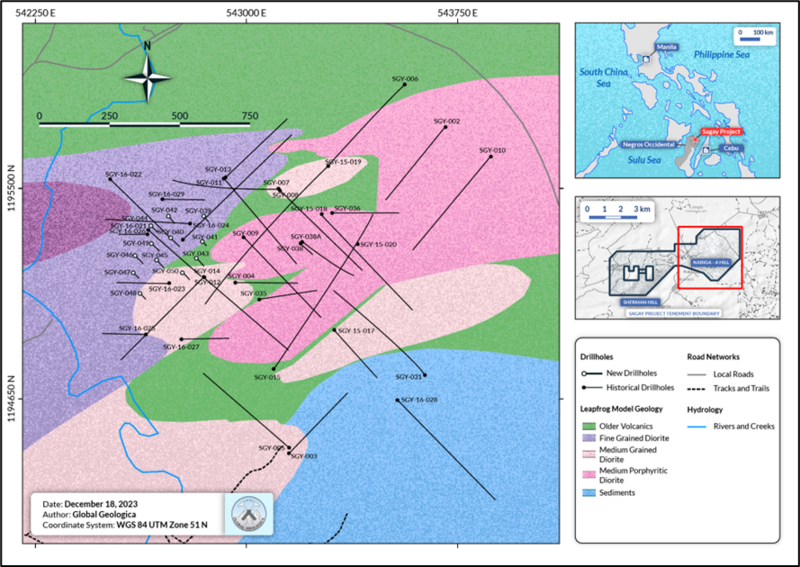

Sagay is located at the northernmost tip of the NNE trending volcanic arc related to the eastward subduction beneath the Negros Trench in the southwest offshore of Negros Island. Several porphyry and epithermal mineralisation targets belong in this underexplored mineralisation trend along the eastern side of the island.

The major rocks identified at Purok Tan-ao are a series of intermediate igneous rocks intruding into older host rocks composed of basalts overlain by metamorphosed sedimentary rocks and felsic volcanics. These rocks are in turn overlain by Quaternary pyroclastic rocks that consist of tuff and tuff breccias. The intermediate intrusions include several diorites and andesite porphyry.

Three distinct Diorite intrusives were identified. Following the local nomenclature in Sagay Project, these are (from oldest to youngest) the (1) Equigranular Diorite (MEQ), (2) Medium-grained Porphyritic Diorite (MPOC), and the (3) Fine-grained Equigranular Diorite (FEQ). These intrusive rocks have distinct textures and visible cross cutting relationships. Widespread strong silica - clay and outer chlorite alteration is notable in the deposit. This 8km by 4km alteration zone is indicative of a large magmatic hydrothermal system.

There are multiple types of porphyry mineralisation observed within the Purok Tan-ao Deposit. The dominant type is related to early-stage porphyry quartz stockwork veins with associated potassic alteration and chalcopyrite as the dominant copper sulphide. A later-stage porphyry Cu-Mo type mineralisation has been identified and is hosted in silica – sericite – chlorite alteration. In addition, evidence exists for a later-stage epithermal vein deposit type which exist within close proximity to the large-scale porphyry copper-gold mineralisation.

At this stage, only the porphyry copper-gold type of deposit was defined in the MRE.

Initial diamond drilling was conducted between December 2012 and 2016 by Freeport-McMoRan, who completed a total of 28 drill holes at Purok Tan-ao, with an aggregate core depth of 22,516.70 metres.

From November 2021 to April 2022, Celsius has completed a total of 4 drill holes and 1 offset, for a total to 2,440 metres. More recently in late 2023, Celsius completed a further 12 shallow drill holes which are the focus for this Mineral Resource update. These shallow drill holes relate to the 900SG mineralised domain with a total meterage of 824.7m.

Sampling and Sub-sampling Techniques

The following sub sampling and sample preparations were followed for all the diamond drilling at Sagay.

Half core samples were collected from diamond holes drilled from the surface. All drill cores were generally sampled at 2m intervals. In cases where geological and mineralogical characteristics change, the sample length is reduced to best fit the geological contact, with a minimum observed sample size of one metre. Sampling typically commenced after the overburden horizon depth was exceeded.

Cut samples were bagged on site prior to delivery to the laboratory (Intertek) in Manila for sample preparation and analysis.

Sample Analysis Method

All samples were analysed at the Intertek, an internationally recognised and ISO/IEC 17025:2005 & ISO/IEC 17020:2004 certified independent laboratory in Manila.

Copper (Cu) values were analysed by means of multi-acid (4-acid) digest. Elements were determined by ICP-OES/MS with AAS finish. Samples were fire assayed for gold (Au) using a 50-gram charge, with a detection limit of 0.005 ppm.

Estimation Methodology

A parent cell block size of 10m x 10m x 10m was chosen based on the general dimensions of the interpreted ore domains, and the likely mining method.

Ordinary Kriging was chosen as the interpolation method for the block model which defines the MRE.

The parameters for Ordinary Kriging were based on an analysis of the variograms for each domain in addition to some broad assumptions with regards to the direction and continuity of the copper and gold mineralisation associated with each defined mineralised domain. The variograms were located along the plane of the interpreted controlling geological trend which is striking at approximately 50 degrees at a near vertical dip.

A broad review of the statistics for each domain did not identify significant high value outliers that are considered likely to result in an overestimated either locally or globally to the grade distribution within the block model. Therefore, no top cut was applied to the MRE.

Classification Criteria

The mineralisation is constrained within boundaries which are also considered to define the limits for each domain as supported by the current drill hole information. Within these domain constraints, minimum search distances and composited drill hole information parameters determined which locations were defined as Measured, Indicated, Inferred or as further Exploration Targets.

A small portion of the 900SG was classified in the Measured category where there is tighter drill spacing (less than 50m), multiple drill holes which show continuity of mineralisation and the variogram analysis is also supporting of the relationship of the assay data between drill holes.

The Indicated category was classified based on maximum distance of 150m to the major position, 85m to the semi-major axis and 25m in the minor direction for the limits, with a minimum number of samples at 8 and maximum number of samples at 16. A minimum of two drill holes was also applied for the Indicated category.

The Inferred Mineral Resource represents over 90% of the total MRE due to the thick and broadly spaced copper intersections as deeper levels which contain the most copper mineralisation identified to date at Purok Tan-ao. This category was extended for twice the distances applied to the Indicated Resource pushing the limits search ellipse to 300m x 150m x 50m, with a minimum of four samples and maximum of 20 samples defined for each block.

No restriction on the number of drill holes was applied for the Inferred Mineral Resource category.

Cut-off Grade

A preferred lower cut-off grade of 0.2% copper has been used in the reported MRE. This is considered appropriate based on the geological continuity associated with copper mineralisation above 0.2% copper in addition to a broad economic cut-off point based on a ~US$10,000/t copper price.

Dimensions

The mineralisation at Purok Tan-ao is classified as a porphyry copper-gold deposit which, at deeper levels (below 400m depth), has a broad geometry of up to 1km along strike towards the north-east (with a main trend of ~45o azimuth) and true widths of up to 280m. At shallower levels, the copper mineralisation is broken up into multiple domains which are individually up to 600m along strike and with true widths of up to 150m.

The 900SG domain is a shallow, flat lying zone of mineralisation which has formed along the current and ancient water table at a broadly horizontal orientation. This domain is elongated in the direction of some interpreted controlling faults and/or source porphyry copper mineralisation. These trends appear to be both north-east and north-west in orientation.

Possible later mining development costs of US$10/t to US$7/t and processing costs of US$7/t to US$4/t respectively for a medium sized (5Mt to 10Mt per annum) underground block caving mining method and processing using floatation (to produce a copper-gold concentrate) have been assumed where applicable for the MRE.

This cost range estimate matches closely with a broad geological cut-off grade of between 0.15% copper and 0.25% copper (at a forward-looking Copper Price of ~US$10,000/t).

Study Results

Based on the resource model, mining parameters, and metallurgical test works, a Mining Project Feasibility Study was submitted to the Philippine Mines and Geosciences Bureau on 20 December 2023 confirming the presence of minerals in the area which are recoverable by processing the ore through gravity separation which was determined to be economically sound, ensuring environmental protection and preservation methods would be implemented through the advanced mining technologies.

The study focused on the shallow supergene chalcocite deposit which is suitable for a medium-scale surface mining operation. The copper concentrate produced will have no deleterious elements which makes it highly marketable.

Technical, environmental, and social considerations were incorporated in the mine design to reduce the mine footprint to approximately 20 hectares. The process plant is engineered to enhance the ore through a gravity concentration method which is effective in extracting valuable components form the ore, thus contributing to the overall success of the ore beneficiation process.

Metallurgical test works indicated that the tails produced is non-acid generating. All tailings will be managed through dry stacking method which eliminates the need for a tailings dam, thus removing the possibility of environmental impacts (tailings spill). Other alternative disposal methods are currently being studied, including the potential use of tailings for hollow block manufacturing as a community livelihood program, road base, and landfill among others.