Tailings dams are the most common means of waste disposal in the mining industry because of their ability to hold huge amounts of material, as well as cost effectiveness. Tailings dams can represent an ongoing liability, long after mine operations cease and facilities are closed and reclaimed. There is a global drive to ensure tailings dams are engineered during construction and evaluated for closure following the end of production.

A tailings dam failure is defined as a physical breach of the dam followed by uncontrolled and typically sudden release of stored materials (e.g., fluids, tailings, sludge, etc.). There are several cases per year of significant failures, with many of these claiming lives. As an industry, we have a duty of care to improve approaches and ensure risks are lowered. Often complacency in operations and storage with an approach of “doing the minimum’’ is not the best practice, and every engineer and organization must do better to raise the bar and protect the lives and environments surrounding these often huge structures.

In the Philippines, with our frequent and often severe earthquakes, tailings dams require robust engineering, high quality monitoring and civil, geotechnical and environmental engineering assessments to ensure the sites are stable long after a mine is a distant memory.

Stability assessments referred to as a Tailings Dam Breach Analyses (TDBA) are a common approach to investigating tailings dams, and this requires detailed, high quality site investigation works. This is where RDCL provides various geotechnical and geophysics techniques that feed engineering data into ground models for breach analyses.

The most common forms for geotechnical investigations are drilling and installation of ground water piezometers. RDCL takes intrusive testing beyond drilling with highly accurate Cone Penetrometer Testing (CPT) and seismic testing.

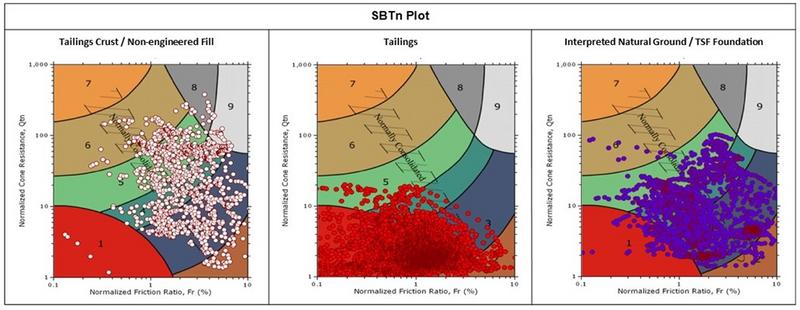

The cone of the CPT rig is made up of load cells or pressure sensors, collecting a variety of data used directly in engineering calculations. CPT testing is calibrated to international standards, and is repeatable. The data is digital, and the quality control checks during testing removes the risk of collecting poor data, leading to poor engineering assumptions. Do it right to design it right, remove the requirement for over-engineering which can lead to significant cost increases.

RDCL operates GeoMil CPT rigs in Philippines and has tested to 68 m below ground in tailings dams. Typically, CPT tests reach depths of 20-30 m. In one day 6-8 CPT tests can be completed, pending site constraints.

The CPT rig also has options to deploy seismic geophones, soil samplers and electronic shear vanes, all of which allow discreet soil testing at specific depths. These additional tools, all part of the Geomil suite of equipment allow in-situ measurements of soil characteristics targeting specific layers within tailings, often to determine liquefaction risk.

RDCL often recommends more than CPT and drilling data across tailings dams, as both techniques are vertical datasets, effectively creating a series of pin-point datasets across often very large areas. This leads to interpolation between datasets, and generalization of ground features.

Surface seismic testing can provide 2D profiles across tailing dams, linking drilling or CPT data creating with good visualizations improving the understanding of soil characteristics across sites.

Two common seismic methods are used;

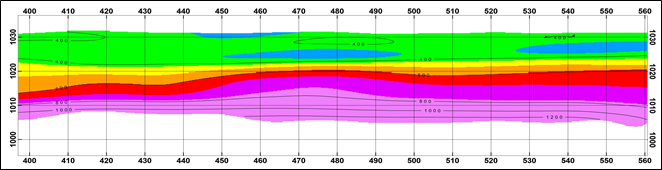

- MASW (Multi-channel Analysis of Surface Wave), deliver Shear wave (Vs) data

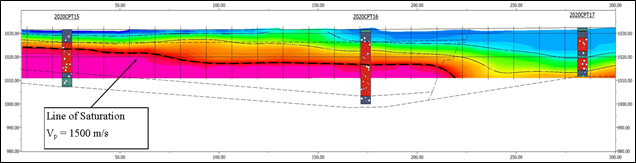

- SRT (Seismic Refraction Tomography), delivers compressional wave (Vp) data

The deployment of surface seismic methods typically involving a long seismic array of 24 to 48 geophones in a straight line and seismic shots (mostly via a sledge hammer), which propagate along and through the ground generating profiles as shown in this article.

Engineering modulus and Poission’s ratio are a common output from seismic surveys. And ground water levels are also derived, via the compressional wave velocity (Vp). A measure of 1500m/s Vp in soils indicates the soils are >99% saturated – and may be prone to liquefaction.

Seismic Refraction Tomography (SRT) is a good way to define the saturation level of soils, 1500m/s Vp indicated >99% saturation. This provides are very useful “delineation” of where tailings materials may liquefy. This interface between dry and saturated tailings allows determination of groundwater level geometries.

Multi-channel Analysis of Surface Waves (MASW) can provide information on the internal structure of enclosing material, as shown in the equations above. The Vs of soils increases as soil stiffness increases. A high Vs means a higher shear strength. When an earthquake shears the ground, soils with a low Vs are more prone to liquefy if they are silts and sands.

In summary tailings dams are not naturally occurring, consolidated deposits. They are often accumulated in very short time scales and can be prone to failure.

If Tailings dams are engineered, monitored and have robust testing techniques described here, we, as an industry, can lower the risk of catastrophic failures improving the lives of everyone involved working on them and living around them.